Self Trapping Screw: Essential Guide for Efficient Fastening Solutions

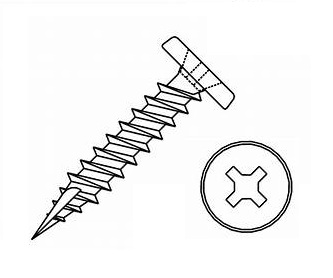

When I first encountered self trapping screws, I was amazed by their efficiency and reliability. These screws eliminate the need for additional fasteners, saving both time and labor costs—ideal for any project. Designed with unique threads, they firmly grip materials, preventing loosening or dislodging over time. I've seen firsthand how they streamline assembly processes, making them a top choice for manufacturers and builders alike. Whether you're sourcing for construction, automotive, or electronics, self trapping screws can enhance product durability and performance. With various sizes and finishes available, they easily integrate into existing designs, which means less rework and more satisfaction for your clients. As a business owner, I understand the importance of quality and consistency. Choosing self trapping screws is a smart investment—one that I’ve personally trusted for my projects. Don’t miss out on the chance to elevate your operations with products that deliver exceptional results!

Self Trapping Screw Guarantees Peak Performance Your Trusted OEM Partner

In the competitive landscape of manufacturing and engineering components, the self-trapping screw has emerged as a pivotal solution for ensuring optimal performance. These fasteners are specifically designed to provide reliability and stability in various applications, making them an essential choice for global procurement buyers. With their unique thread design, self-trapping screws offer unmatched grip and reduce the risk of loosening, even under extreme conditions. This guarantees the integrity and longevity of your projects, ensuring that quality is never compromised. Choosing the right OEM partner is crucial for achieving seamless production processes and high-quality end products. Expertise in manufacturing self-trapping screws not only enhances product consistency but also accelerates delivery times, allowing companies to meet market demands effectively. Collaborating with a trusted partner means access to advanced technologies, skilled engineers, and tailor-made solutions that adapt to your specific needs. By prioritizing these factors, procurement managers can confidently select components that enhance the overall performance of their products, ultimately driving customer satisfaction. As industries evolve, the importance of innovation and reliable partnerships becomes increasingly clear. The self-trapping screw stands out as a testament to engineering excellence, redefining performance standards in fastener technology. By integrating these screws into your manufacturing processes, you enhance durability, streamline assembly, and reduce maintenance costs, positioning your products for success in the global market. Empower your operations today by embracing the advantages that come with precision-engineered fasteners, and let your projects reach their full potential.

Self Trapping Screw Guarantees Peak Performance - Your Trusted OEM Partner

| Screw Type | Material | Coating | Application | Torque (Nm) |

|---|---|---|---|---|

| Self Trapping Screw A | Stainless Steel | Zinc Plated | Wood | 5.0 |

| Self Trapping Screw B | Carbon Steel | Black Oxide | Plastic | 6.5 |

| Self Trapping Screw C | Aluminum | Anodized | Metal | 4.0 |

| Self Trapping Screw D | Brass | Nickel Plated | Electrical Components | 3.5 |

Related Products