Top Rigging Hardware for Efficient Lifting: Quality and Durability

When it comes to rigging hardware, I know quality and reliability are key for your projects. Our range of rigging hardware is designed to meet the demands of professionals in various industries, ensuring safety and efficiency. Whether you're searching for durable lifting slings or sturdy shackles, you'll find exactly what you need in our extensive collection. I understand that time is money; that's why we prioritize prompt shipping and exceptional customer service. Our products are rigorously tested to handle the toughest conditions, giving you peace of mind while you work. I remember the frustration of using inferior equipment, and that's why I’m committed to providing only the best. Your projects deserve nothing less. If you're exploring options for high-quality rigging hardware, let us help you elevate your operations and achieve your goals with confidence. Quality, dependability, and a focus on your needs—trust us to deliver what you’re looking for.

Rigging Hardware Application Is The Best

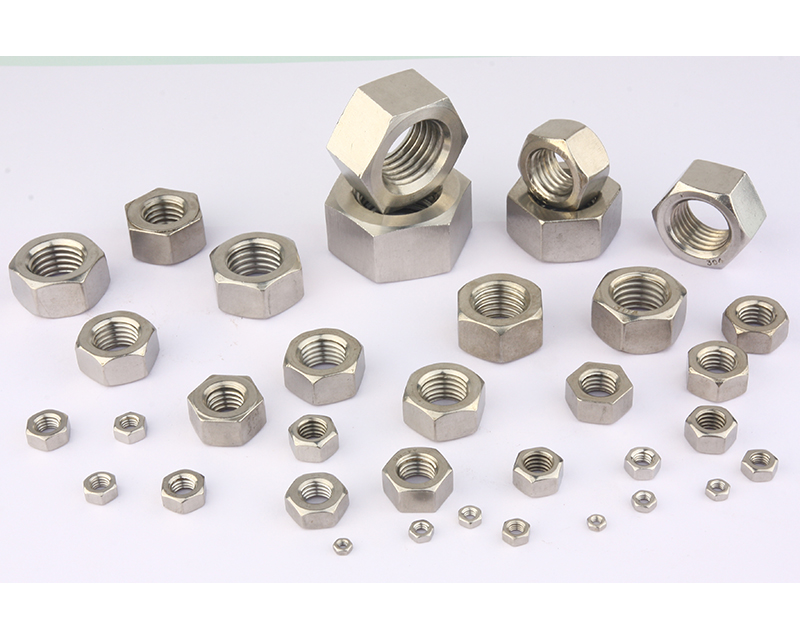

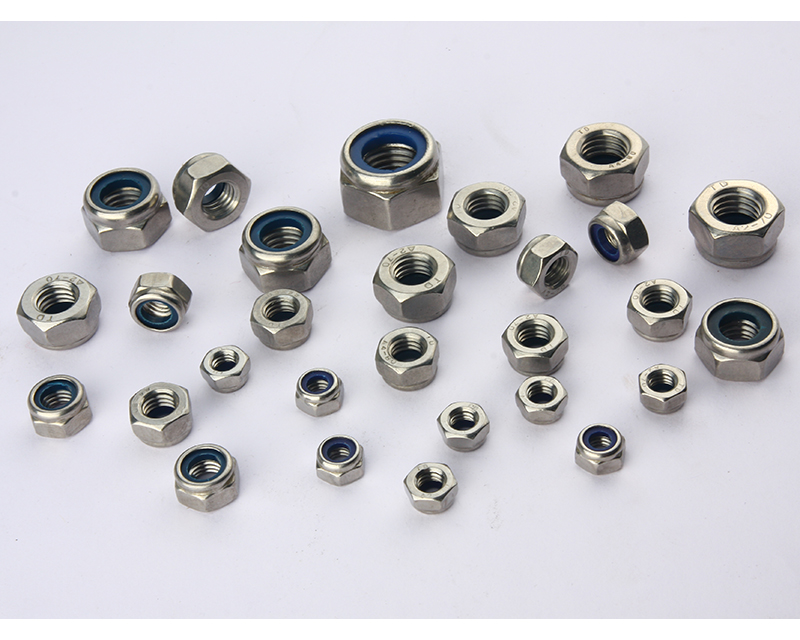

When it comes to rigging hardware, the application and adaptability of these tools are crucial for industries ranging from construction to entertainment. Rigging hardware serves as the backbone for lifting, securing, and stabilizing heavy loads, ensuring safety and efficiency in operations. With a diverse array of products including shackles, slings, pulleys, and connectors, the right choices can make all the difference in achieving operational excellence. Global procurement professionals are increasingly focused on finding reliable suppliers that can provide high-quality rigging solutions tailored to their specific needs. Understanding the unique demands of various industries is essential. For example, in the construction sector, heavy-duty hardware with robust specifications is required to withstand harsh conditions, while industries like film and theater benefit from lightweight yet strong materials that enable intricate rigging setups. Collaborating with manufacturers who emphasize quality control and innovation in rigging hardware can lead to enhanced performance and reduced downtime. Investing in top-notch rigging hardware not only reduces risks but also optimizes operational workflows. With the right hardware, projects can proceed more smoothly, freeing teams to concentrate on their core tasks. As the demand for advanced rigging solutions grows, aligning with manufacturers that prioritize durability, safety, and versatility will ensure successful operations across various fields.

Rigging Hardware Application Is The Best

| Application Area | Rigging Hardware Type | Material | Load Capacity (tons) | Usage Examples |

|---|---|---|---|---|

| Construction | Shackles | Steel | 10 | Lifting beams, hoisting loads |

| Theatrical Events | Carabiners | Aluminum | 5 | Hanging lighting, sound equipment |

| Marine | Pulley Blocks | Stainless Steel | 15 | Sailing, rigging sails |

| Aerial Work | Slings | Nylon | 3 | Maintenance of high structures |

| Automotive | Hooks | Carbon Steel | 8 | Tow vehicles, recovery operations |

Related Products