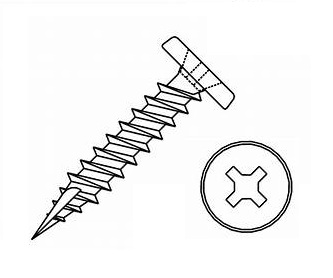

Find the Best Philips Head Screws for Your DIY Projects and Repairs

When I needed reliable fasteners, I found the Philips Head Screw to be the standout choice for my projects. Its unique design offers exceptional grip, making it easy to drive and ensuring secure fastening every time. I appreciate how it reduces slippage, which saves me time and effort on the job. Plus, the quality of these screws means they can withstand various environments, whether for indoor or outdoor use. These screws are not just practical; they meet high standards of durability that I can count on for long-term applications. When I’m sourcing materials, I always consider performance and value; the Philips Head Screw ticks all the boxes. They’re available in various sizes, making them perfect for any task, from simple repairs to complex assemblies. By choosing this screw, I can ensure that my projects stay sturdy and reliable.

Philips Head Screw Market Leader Delivers Unmatched Quality

In today's competitive manufacturing landscape, securing high-quality components is crucial for operational success. The Philips head screw, known for its unique design that provides enhanced torque and grip, has become a staple in various industries, from automotive to electronics. As global demand rises, leading manufacturers are stepping up to meet the needs of international buyers by delivering uncompromising quality and innovation. At the forefront of this movement is a company renowned for its commitment to excellence in hardware production. With state-of-the-art facilities and a focus on advanced manufacturing techniques, they ensure that each screw adheres to stringent quality standards. Rigorous testing processes guarantee durability, precision, and compatibility, fulfilling the diverse requirements of global procurement professionals seeking reliable solutions for their projects. Moreover, sustainability is becoming a defining factor in procurement decisions worldwide. By implementing eco-friendly practices and sourcing responsibly, leading manufacturers in the industry not only provide high-quality products but also contribute to a greener future. As they continue to evolve and innovate, these key players are well-positioned to address the growing demands of global markets, making the Philips head screw an essential component in countless applications across the globe.

Philips Head Screw Market Leader Delivers Unmatched Quality

| Screw Type | Material | Coating | Head Size (mm) | Drive Type | Application |

|---|---|---|---|---|---|

| PH 10 | Steel | Zinc Plated | 4.5 | PZ | Wood |

| PH 12 | Stainless Steel | Black Oxide | 5.0 | PZ | Metal |

| PH 14 | Brass | Natural | 6.0 | PZ | Plastic |

| PH 16 | Carbon Steel | Galvanized | 7.0 | PZ | Furniture |

Related Products