Top Quality Oxide Screws for Durable Projects - Affordable Prices

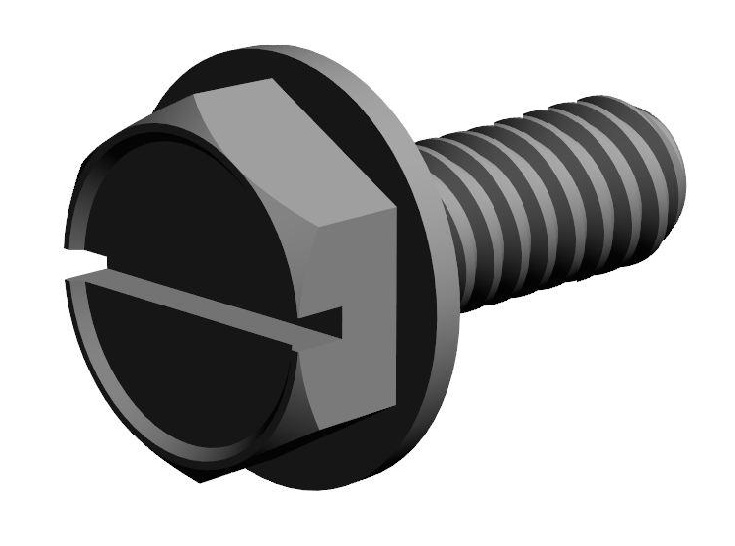

When I first explored the world of fasteners, I quickly realized how crucial quality is, especially with something like an Oxide Screw. These screws are not only designed to stand the test of time, but they also offer excellent resistance against rust and corrosion, making them ideal for various applications. With a reputation for durability and performance, I can see why buyers in industries spanning from construction to manufacturing are keen on them. The unique oxide coating creates an additional layer of protection, ensuring reliability even in harsh environments. Plus, the precision engineering guarantees a snug fit, reducing the risk of wear and tear. I’ve had firsthand experience sourcing Oxide Screws for major projects, and I can say that they’ve consistently met the demands of my clients. By prioritizing quality and compatibility, you can trust that these screws will exceed your expectations and enhance your operations.

Oxide Screw Products Trusted by Pros

In the ever-evolving landscape of industrial hardware, quality and reliability are paramount. Professionals across various sectors are consistently seeking suppliers that can deliver products meeting rigorous standards. One such product that stands at the forefront of industrial excellence is the oxide screw. These screws, renowned for their superior corrosion resistance and enhanced durability, are increasingly becoming the preferred choice among industry experts. A key advantage of oxide screws lies in their manufacturing process, which involves an innovative coating technique that not only boosts their longevity but also minimizes maintenance concerns. They can withstand harsh environments, making them ideal for applications in construction, automotive, and machinery sectors worldwide. As global procurement trends shift towards suppliers who can offer both quality and adaptability, choosing oxide screws can contribute significantly to operational efficiency and cost-effectiveness. Moreover, the growing demand for sustainable and high-performance materials has created an opportunity for businesses to align with suppliers focused on innovation and eco-friendly practices. By leveraging the benefits of oxide screws, procurement professionals can enhance their supply chains while ensuring compliance with international quality standards. As industries gear up for the future, investing in these trusted products is a strategic move that can provide significant advantages in a competitive marketplace.

Oxide Screw Products Trusted by Pros

| Product Type | Material | Finish | Size (mm) | Used For |

|---|---|---|---|---|

| Wood Screw | Steel | Zinc Plated | 25 | Wood Applications |

| Machine Screw | Stainless Steel | Passivated | 10 | Metal Assemblies |

| Self-Tapping Screw | Carbon Steel | Black Oxide | 20 | Plastic Applications |

| Lag Screw | Bronze | Plain | 30 | Heavy Duty Construction |

| Drywall Screw | Phosphated Steel | Gray | 35 | Sheetrock Materials |

Related Products