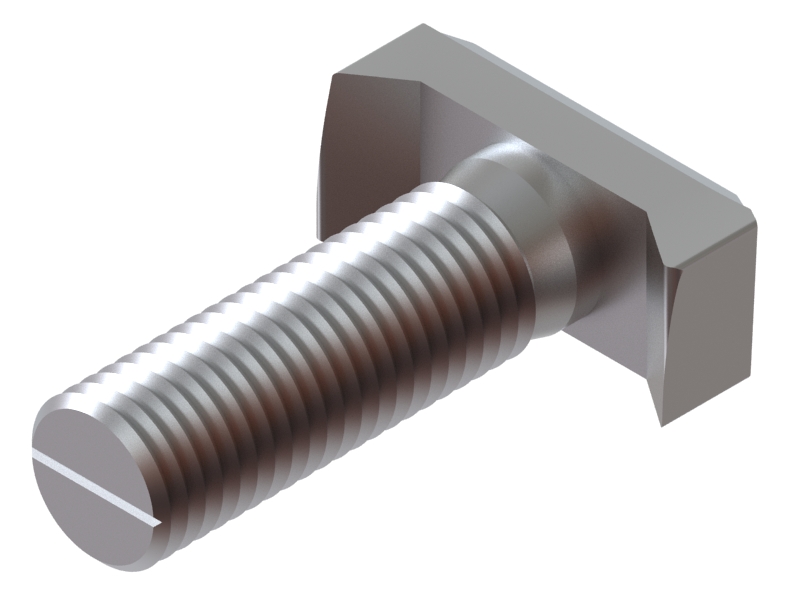

Non-Standard T Bolt: Essential Features and Benefits Explained

When I first came across the Non-standard T Bolt, I was amazed by its versatility and strength. These bolts are perfect for those who need custom solutions for their specific applications, offering the added benefit of customization options. I know how crucial it is for businesses to find reliable fasteners that meet unique requirements without compromising on quality. Whether you're in construction, machinery, or any industry that demands reliability, these Non-standard T Bolts will cater to your needs. The robust design ensures a tight grip, making them an ideal choice for load-bearing structures. Plus, with various materials and finishes available, you can match your project specifications perfectly. I've seen many companies benefit from using these bolts for their unique projects, enhancing their operational efficiency. If you're trying to boost performance or ensure safety, having the right fasteners can make all the difference. I’m confident that our Non-standard T Bolts will exceed your expectations and help solve your fastening challenges.

Non-standard T Bolt Stands Out Factory-Direct Excellence

In today's competitive marketplace, finding reliable and high-quality products can be a challenge for global buyers. One category that has made significant strides is non-standard T bolts, which have become essential for various applications across different industries. Their unique design allows for versatility and ease of use, which is especially valuable in sectors like construction, automotive, and machinery. What sets factory-direct excellence apart is the emphasis on quality control and cost-effectiveness. By sourcing directly from manufacturers, buyers can ensure that they are receiving products that meet stringent quality standards without the added expenses associated with intermediaries. With non-standard T bolts, customization options are also more accessible, allowing businesses to tailor their orders to better suit their specific needs. Investing in non-standard T bolts sourced directly from a reputable manufacturer not only guarantees superior performance but also fosters a strong partnership that can lead to ongoing support and innovation. As industries evolve, staying ahead requires access to cutting-edge solutions, and these factory-direct products are an excellent way to meet those demands efficiently and affordably.

| Dimension | Material | Finish Type | Load Capacity | Application |

|---|---|---|---|---|

| M8 x 30mm | Stainless Steel | Zinc Plated | 450 kg | Automotive |

| M10 x 50mm | Carbon Steel | Black Oxide | 600 kg | Construction |

| M12 x 40mm | Alloy Steel | Galvanized | 800 kg | Heavy Machinery |

| M6 x 20mm | Aluminum | Anodized | 200 kg | Electronics |

| M16 x 70mm | Stainless Steel | Polished | 1000 kg | Marine |

Related Products