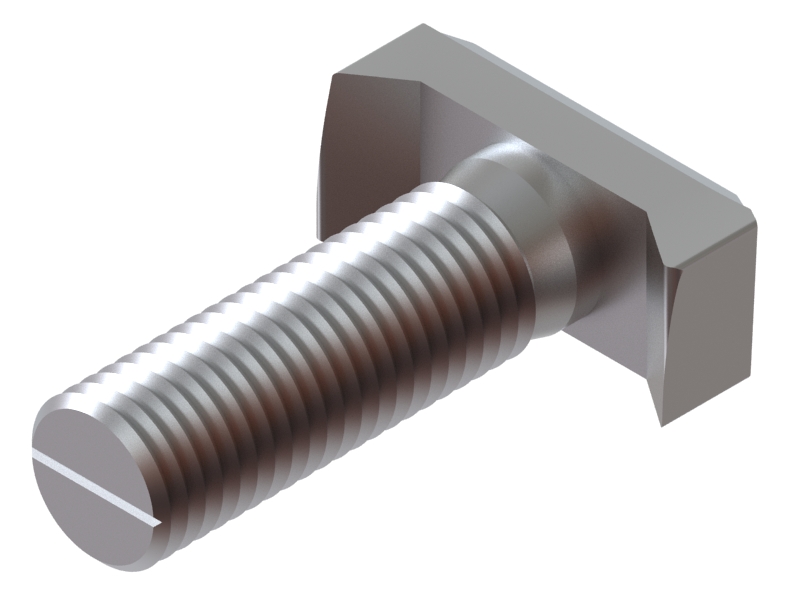

Flat Square Head Bolt: Durable Fasteners for Every Project Need

When I think about the essential components in any assembly, the Flat Square Head Bolt always comes to mind. These bolts are perfect for applications where a flush finish is desired, providing a sleek appearance without compromising strength. With options available to suit various materials and load requirements, they suit both large-scale manufacturing and small projects. I know that ease of use is important, which is why the design allows for quick installation and a secure fit. Whether you’re in construction or machinery assembly, these bolts deliver reliable performance every time. Plus, the durability of these fasteners means they can withstand tough conditions, making them a go-to choice for professionals looking for quality. If you need bulk quantities or only a few pieces, we’ve got you covered. Let me help you find the right Flat Square Head Bolt for your needs—quality, dependability, and efficiency are just a call away!

Flat Square Head Bolt Guarantees Peak Performance Exceeds Industry Benchmarks

When it comes to fastening solutions that promise superior performance, flat square head bolts stand out in various industrial applications. Designed to exceed industry benchmarks, these bolts offer exceptional strength and durability, ensuring that they perform reliably under pressure. Their unique flat square head design not only enhances grip ability but also accommodates higher torque applications, making them a favorite among engineers and project managers worldwide. Global buyers seeking high-quality fastening solutions will find that flat square head bolts provide a significant advantage in product integrity and efficiency. With stringent quality control measures implemented during the manufacturing process, these bolts deliver consistent performance across different conditions. Industries such as construction, automotive, and machinery benefit from the precision and reliability of these fasteners, which are capable of withstanding varying levels of stress and environmental factors. Investing in advanced fastening technology like flat square head bolts translates to improved operational efficiency and safety in any project. As industries strive for perfection, these bolts not only meet the demands of modern engineering but also set new standards in performance and longevity. By choosing high-performance fasteners, global purchasers can ensure the success of their projects while adhering to best practices and compliance regulations.

Flat Square Head Bolt Guarantees Peak Performance Exceeds Industry Benchmarks

| Dimension | Material | Coating | Tensile Strength (MPa) | Applications | Certification |

|---|---|---|---|---|---|

| 10mm x 50mm | Carbon Steel | Zinc Plated | 400 | Construction, Machinery | ISO 9001 |

| 12mm x 75mm | Stainless Steel | Passivated | 600 | Aerospace, Marine | ASTM A193 |

| 16mm x 100mm | Alloy Steel | Black Oxide | 850 | Automotive, Industrial | DIN EN 15048 |

| 8mm x 40mm | Carbon Steel | Hot-Dip Galvanized | 500 | Heavy Machinery | ISO 14001 |

| 14mm x 80mm | Stainless Steel | Electrophoretic Coating | 700 | Marine, Construction | JIS G3101 |

Related Products