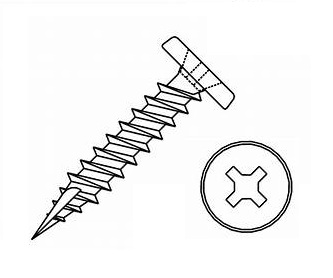

Top Wood Screws for DIY Projects: Durable, Reliable, and Easy to Use

When I'm sourcing the right fastening solutions, the wood screw always stands out. Its versatility and strength make it ideal for a variety of woodworking projects, from constructing furniture to doing home repairs. I know that durability matters in any business, and these screws are designed to withstand heavy loads without compromising quality. What I appreciate most is the ease of installation – the sharp tip and threaded design grip the wood firmly, ensuring everything stays in place. If you’re after reliability and performance, look no further; these wood screws deliver just that. My experience shows that customers notice the difference in their projects once they switch to these screws. Plus, they come in different sizes, so I can always find what I need for any job. So, when you want to elevate your craft and ensure long-lasting results, investing in quality wood screws is a no-brainer.

wood screw Industry Giant Guarantees Peak Performance

In the competitive landscape of the wood screw industry, performance and reliability are paramount for manufacturers and suppliers alike. Leading industry players understand that their reputation hinges on high-quality products that meet the rigorous demands of various applications. With advanced technology and innovative manufacturing processes, companies are now able to guarantee not just durability but also precision engineering in their wood screws. A focus on peak performance involves comprehensive quality control measures, ensuring that each screw produced meets international standards. This commitment to excellence resonates with global buyers who seek trustworthy partners in their supply chain. The industry's giants often leverage extensive R&D efforts to enhance product offerings, incorporating features that improve usability and efficiency in diverse woodworking projects. As a result, procurement specialists can confidently recommend these products, knowing they will deliver outstanding results and foster customer satisfaction. Moreover, as sustainability becomes a key consideration for many businesses, leading manufacturers are increasingly adopting eco-friendly practices in their production lines. By utilizing sustainable materials and implementing waste-reduction strategies, these companies not only appeal to environmentally-conscious consumers but also establish themselves as responsible players in the global marketplace. For procurement professionals looking for reliable partners, aligning with these industry giants promises not only quality and performance but also a commitment to a sustainable future.

Wood Screw Industry Giant Guarantees Peak Performance

| Dimension | Material | Coating Type | Drive Type | Strength (psi) | Usage |

|---|---|---|---|---|---|

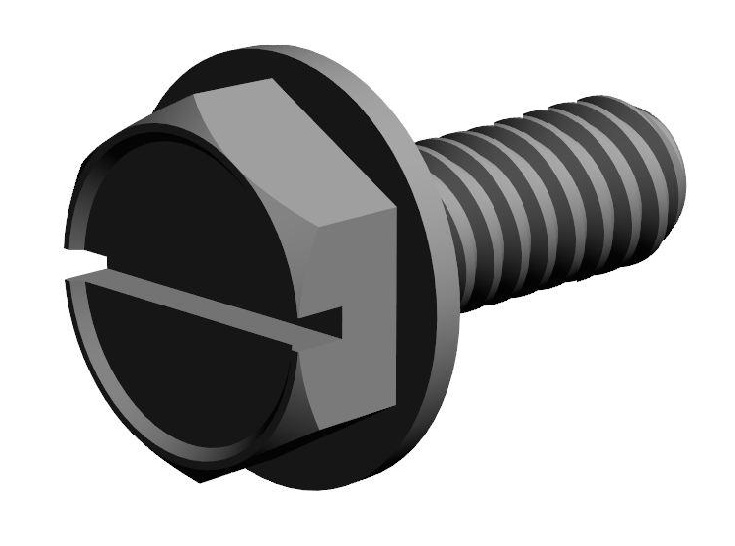

| #8 x 1.25 | Stainless Steel | Zinc Plated | Phillips | 120,000 | Wood, Decking |

| #10 x 1.5 | Carbon Steel | Black Oxide | Square | 140,000 | Plywood, Furniture |

| #12 x 3 | Brass | Natural Finish | Torx | 160,000 | Cabinetry, Trim |

| #14 x 2.5 | Aluminum | Anodized | Slotted | 180,000 | Electrical Applications |

| #6 x 1 | Plastic | UV Resistant | Hex | 100,000 | Outdoor Fixtures |

Related Products