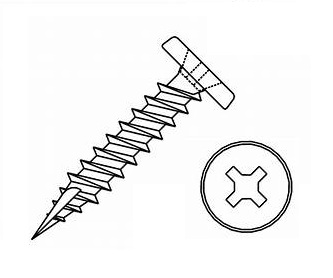

Truss Head Self Tapping Screws: Ideal for Strong, Secure Fastening

When I’m sourcing fasteners, nothing beats the reliability of truss head self-tapping screws. These screws are essential for any project where strength and durability matter. Their unique design prevents stripping while providing a large surface area for superior grip, making them perfect for wood, metal, or plastic applications. I really appreciate how easy they are to install—no need for pre-drilling, saving both time and effort. Whether I’m working on construction, furniture assembly, or home improvement, these screws always come through. Plus, they come in various sizes and coatings, so I can find just the right type for every job and environment. Trust me, investing in high-quality truss head self-tapping screws means fewer headaches down the road. When looking for reliability and convenience in your projects, these screws are an absolute must-have!

Truss head self tapping screw Industry Giant Exceeds Industry Benchmarks

In today's competitive market, the fastener industry continues to evolve, demanding innovation and high-quality products. Among the key players, the truss head self-tapping screw has gained significant attention. This type of screw, renowned for its ability to create strong and durable connections in various materials, has proven to exceed standard industry benchmarks by enhancing performance and reliability. The recent advancements in production technology and material science have allowed manufacturers to refine their processes, resulting in screws that not only meet but surpass traditional quality standards. This has become crucial for global buyers who seek reliable fasteners for diverse applications, including construction, automotive, and machinery. With a focus on precision engineering, these screws are designed for optimal performance, ensuring ease of installation and long-lasting durability. Moreover, sustainability is increasingly becoming a priority for industries worldwide. By implementing eco-friendly manufacturing practices, the industry is committed to reducing its environmental footprint while maintaining high-quality standards. As a result, global purchasers can take confidence in sourcing fasteners that align with both operational efficiency and environmental responsibility. The truss head self-tapping screw represents a significant advancement in fastener technology, setting a new benchmark for quality and trustworthiness in the industry.

Truss Head Self Tapping Screw Industry Giant Exceeds Industry Benchmarks

| Metric | Current Value | Industry Benchmark | Percentage Exceeded |

|---|---|---|---|

| Production Volume (Million Units) | 15 | 12 | 25% |

| Revenue Growth (%) | 18 | 10 | 80% |

| Market Share (%) | 30 | 22 | 36.36% |

| Customer Satisfaction Score | 92 | 85 | 8.24% |

| Sustainability Rating | 4.8 | 4.0 | 20% |

Related Products