Premium Stainless Torx Screw: Durable Fasteners for Every Project

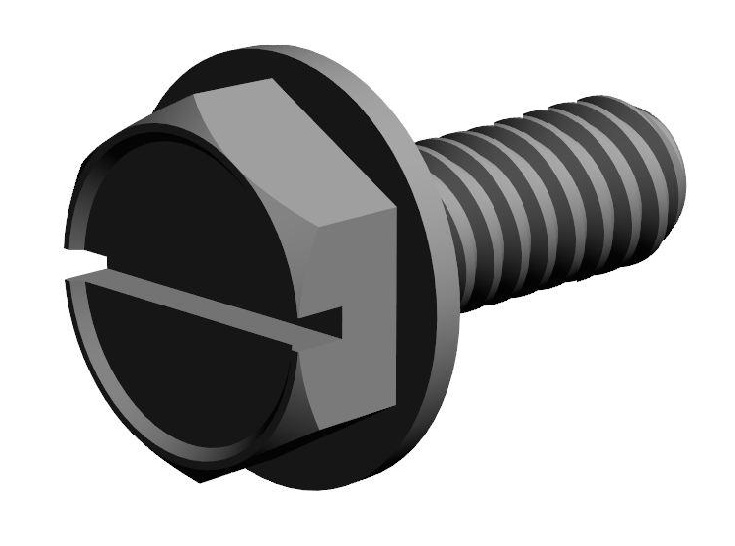

When I need reliable fasteners, I always turn to stainless Torx screws. These screws are not only corrosion-resistant, but their design also provides excellent grip for high-torque applications. I really appreciate how the Torx head allows me to use less effort while ensuring a secure fit, especially in tight spots. Perfect for a variety of industries, stainless Torx screws are a game-changer for assembly and maintenance tasks. I often choose these when I'm focused on durability and performance in the field. Plus, they come in various sizes, making it easy to find the perfect match for any project. By opting for stainless Torx screws, I'm confident in the longevity of my installations. They truly are the top choice for anyone serious about quality fasteners and good value. If you're aiming for strong and reliable connections, these are the screws you need.

Stainless Torx Screw For the Current Year Delivers Unmatched Quality

When it comes to precision and reliability in fastening solutions, stainless Torx screws stand out as a top choice for industries worldwide. This year, the market has seen a surge in demand for high-quality stainless Torx screws, driven by their exceptional performance in various applications. The unique design of the Torx head reduces the risk of cam-out, ensuring that screws are driven in securely, which enhances the overall durability of machinery and structures. Manufactured with premium-grade stainless steel, these screws offer outstanding resistance to corrosion and environmental wear, making them ideal for both indoor and outdoor use. Industries ranging from automotive to construction are increasingly sourcing these screws due to their ability to maintain integrity over time, even in extreme conditions. As businesses focus on quality and longevity in their products, the adoption of stainless Torx screws becomes a strategic move to achieve these goals. Global buyers looking for dependable fastening solutions will find that investing in stainless Torx screws not only meets their quality standards but also ensures operational efficiency. As the demand continues to grow, sourcing these high-quality fasteners is essential for maintaining competitive advantages in various markets. By choosing superior products, companies can improve their overall performance and customer satisfaction.

Stainless Torx Screw For the Current Year Delivers Unmatched Quality

| Screw Type | Material | Size (mm) | Drive Type | Coating | Application |

|---|---|---|---|---|---|

| Torx Screw | Stainless Steel | 4 | T10 | None | Electronics |

| Torx Screw | Stainless Steel | 5 | T15 | Zinc Plated | Automotive |

| Torx Screw | Stainless Steel | 6 | T20 | Black Oxide | Construction |

| Torx Screw | Stainless Steel | 8 | T25 | None | Furniture |

| Torx Screw | Stainless Steel | 10 | T30 | Electroless Nickel | Aerospace |

Related Products