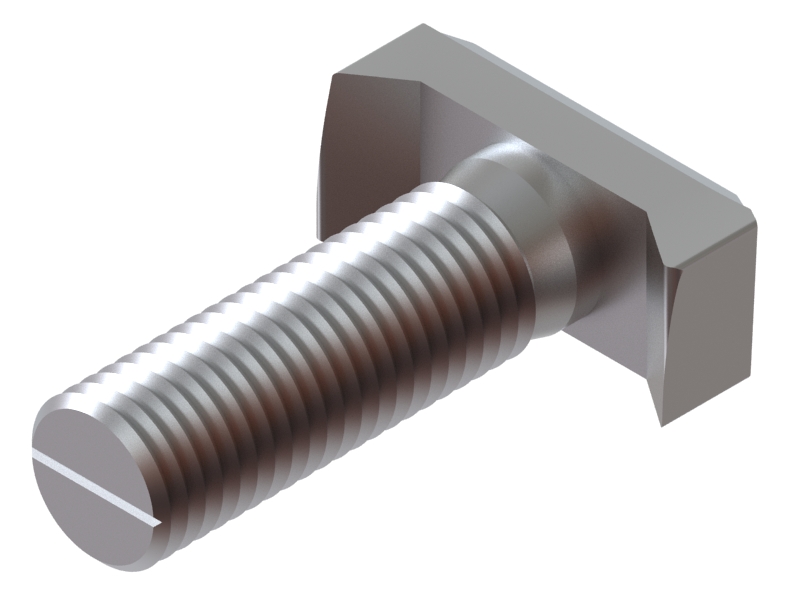

Premium Stainless T Head Bolt for Durable Fastening Solutions

When I needed a reliable fastening solution, I turned to the Stainless T Head Bolt. This bolt is designed for exceptional strength and durability, making it perfect for various applications in construction and machinery. With its unique T-shaped head, it provides excellent grip and stability, ensuring that your projects stay secure. I found that these bolts are not just sturdy but also resistant to corrosion, which is crucial for outdoor and industrial environments. Plus, they come in various sizes, catering to different specifications. Purchasing in bulk is straightforward, and I appreciate how quickly the orders are processed. Not just a product, but a valuable asset for anyone looking to enhance their projects with quality fastening solutions. If you are aiming for reliability and strength, consider adding Stainless T Head Bolts to your toolkit. They may just be what you need to push your projects to the next level.

Stainless T Head Bolt Sets the Industry Standard Where Innovation Meets 2025

As industries evolve, the demand for high-quality fastening solutions continues to rise. The Stainless T Head Bolt Set has emerged as a frontrunner in this sector, setting a new benchmark in both performance and innovation for 2025. These innovative fastening systems are designed to provide superior strength and durability, making them ideal for a variety of applications, including construction, automotive, and machinery. Engineered for excellence, these stainless steel bolts offer exceptional resistance to corrosion and wear, ensuring longevity and reliability even in the harshest environments. Their unique T-shaped head allows for easy installation and a secure grip, minimizing the risk of loosening under vibration. With a commitment to pushing boundaries, manufacturers are continuously improving materials and designs, resulting in products that not only meet but exceed industry expectations. For global buyers seeking to enhance operational efficiency, investing in these advanced T Head Bolt Sets can lead to significant cost savings through reduced maintenance and replacement needs. Embracing this innovation not only positions businesses at the forefront of their industries but also contributes to a sustainable future by utilizing high-quality materials that minimize waste. As we look ahead to 2025, the integration of such innovative fasteners will surely play a key role in shaping the landscape of industrial hardware.

Stainless T Head Bolt Sets the Industry Standard Where Innovation Meets 2025

| Specifications | Material | Finish | Strength (MPa) | Applications |

|---|---|---|---|---|

| M6 x 20mm | 304 Stainless Steel | Passivated | 600 | Automotive, Marine |

| M8 x 25mm | 316 Stainless Steel | Electropolished | 800 | Food Processing, Chemical |

| M10 x 30mm | 304 Stainless Steel | Zinc Plated | 700 | Construction, Machinery |

| M12 x 40mm | A2 Stainless Steel | Clear Passivated | 900 | Marine, Oil & Gas |

| M16 x 50mm | 316 Stainless Steel | Polished | 1100 | High-Pressure Equipment |

Related Products