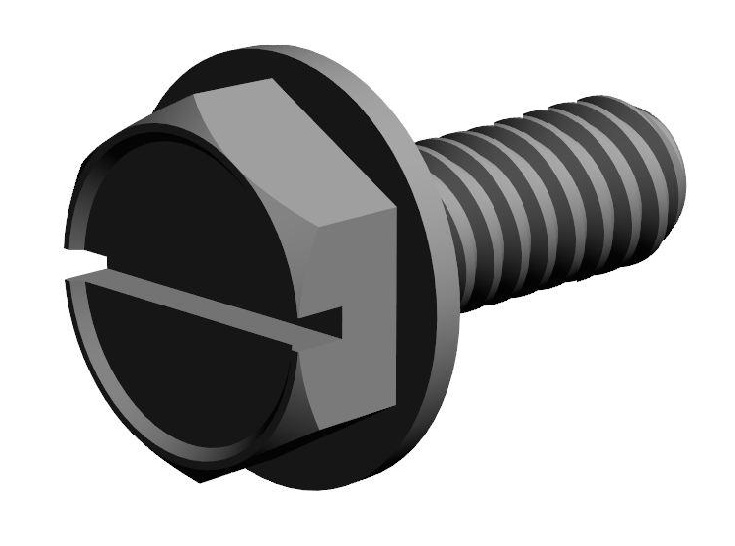

High-Quality Stainless Machine Screws for Reliable Fastening Solutions

When I first encountered stainless machine screws, I was impressed by their durability and resistance to corrosion, making them perfect for a variety of applications. These screws are not just any fasteners; they offer superior strength while accommodating different materials and environments. For anyone in manufacturing or maintenance, having reliable components is crucial, and these stainless machine screws deliver just that. I often find myself recommending them because they're easy to work with and provide a secure fit. Plus, they’re available in various sizes, making them versatile for different projects. If you're prioritizing quality and longevity in your fasteners, these screws should definitely be on your radar. Investing in stainless machine screws means investing in peace of mind. You won't have to worry about replacements anytime soon!

Stainless Machine Screw Industry Giant Where Service Meets Innovation

In the rapidly evolving stainless machine screw industry, innovation and exceptional service are paramount for fulfilling the diverse needs of global buyers. As manufacturers increasingly focus on quality and efficiency, the importance of finding a partner who not only understands the technical aspects of screw production but also prioritizes customer communication cannot be overstated. The confluence of cutting-edge technology and a commitment to client satisfaction ensures that procurement partners receive products that meet their exact specifications. Manufacturers are leveraging advanced production techniques and automation to enhance precision and reduce lead times. This shift allows businesses to respond swiftly to market demands while maintaining the highest quality standards. For global buyers, choosing a supplier that embraces innovation means access to a wider range of products, from customizable screw sizes to tailored solutions that can streamline their supply chains. Moreover, it’s crucial to emphasize the role of robust after-sales support in building long-lasting partnerships. A stellar service experience, characterized by responsive communication and proactive problem-solving, can distinguish a supplier in this competitive landscape. As the industry continues to grow, the synergy of inventive craftsmanship and dedicated service will undoubtedly shape the future of international procurement in the stainless machine screw sector.

Stainless Machine Screw Industry Giant Where Service Meets Innovation

| Dimension | Material | Coating Type | Application | Innovative Feature |

|---|---|---|---|---|

| M2.5 x 10mm | Stainless Steel 304 | Zinc Plated | Electronics | Corrosion Resistance |

| M3 x 20mm | Stainless Steel 316 | Black Oxide | Marine Applications | High Strength |

| M4 x 25mm | Stainless Steel 420 | Passivated | Industrial Equipment | Low Magnetic Susceptibility |

| M5 x 30mm | Stainless Steel 304L | None | Food Industry | Hygienic Design |

| M6 x 40mm | Stainless Steel 316L | Nitrided | Pharmaceutical | Chemical Resistance |

Related Products