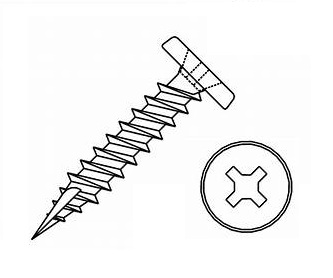

Square Neck Screws: Durable Cap Screws for Reliable Fastening Solutions

When it comes to securing parts with precision, I trust the quality and reliability of square neck screws or cap screws. These fasteners are designed to provide a firm grip, minimizing the risk of loosening over time. Whether I'm working on machinery or assembling furniture, their unique square neck prevents rotation, making installation a breeze. I often recommend these screws because they offer unmatched durability and strength, suitable for various applications. Plus, their compatibility with a range of materials ensures versatility in multiple projects. Buying in bulk not only saves costs but also guarantees that I always have the right fasteners on hand. With a focus on quality and performance, choosing the right square neck screws can make all the difference in a project’s success. If you value efficiency and reliability as much as I do, these screws are definitely worth considering.

Square Neck Screw/cap Screw Dominates Factory-Direct Excellence

In the ever-evolving landscape of manufacturing fasteners, the square neck screw, also known as cap screw, stands out as a critical component that combines functionality and efficiency. Its unique design allows for superior grip and stability, making it ideal for various applications in diverse industries, from automotive to construction. As global demand for robust fastening solutions increases, the factory-direct model has emerged as a key driver of excellence in both product quality and cost-effectiveness. Choosing factory-direct suppliers not only fosters transparency in production but also ensures that buyers have access to the latest innovations in screw manufacturing. By eliminating intermediaries, purchasers can explore a wider range of specifications and customization options tailored to specific project needs. This direct connection facilitates faster response times and enhances the overall procurement experience—an essential factor in today's fast-paced market. To maximize efficiency and reliability in your operations, consider integrating square neck screws into your supply chain. Their inherent strength and versatility meet the demanding standards of contemporary engineering projects, positioning them as a smart investment for companies aiming to elevate their product quality and performance. Embrace the factory-direct approach today to unlock unmatched excellence in your fastening solutions.

Square Neck Screw/Cap Screw Dominates Factory-Direct Excellence

| Type | Material | Coating | Size (mm) | Strength Grade | Applications |

|---|---|---|---|---|---|

| Square Neck Screw | Stainless Steel | Zinc Plated | 10 | A2-70 | Automotive, Furniture |

| Cap Screw | Carbon Steel | Black Oxide | 12 | 5.6 | Construction, Machinery |

| Square Neck Screw | Alloy Steel | Galvanized | 8 | 10.9 | Heavy Machinery, Industrial |

| Cap Screw | Stainless Steel | None | 16 | A4-80 | Marine, Chemical Industry |

Related Products