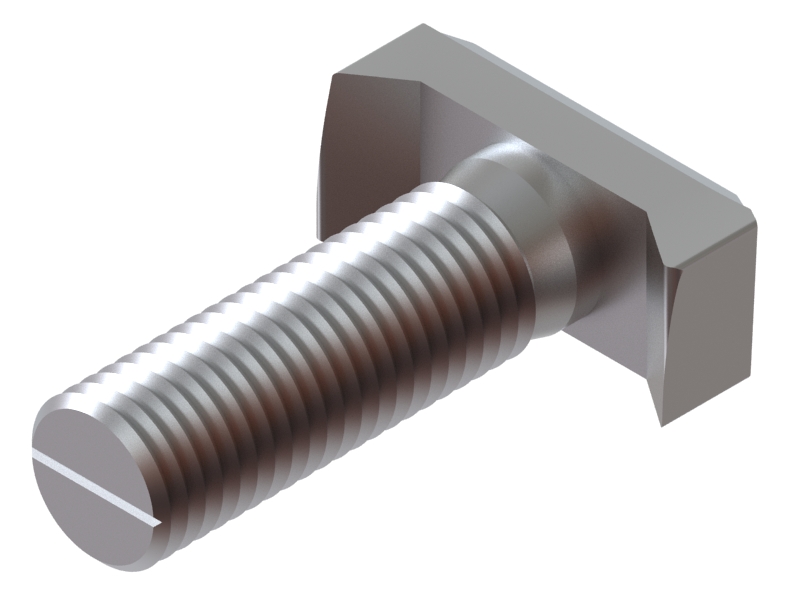

High-Quality OEM Stainless Steel Bolt for Reliable Fastening Solutions

Are you in need of durable and reliable fastening solutions? Our OEM stainless steel bolts are engineered to meet the highest standards of quality and performance. With a variety of sizes and specifications available, these bolts are perfect for various industrial applications, ensuring longevity and strength in any environment. I understand that reliability and precision are crucial when it comes to choosing the right fasteners for your projects. That’s why our stainless steel bolts are resistant to corrosion and wear, making them ideal for both indoor and outdoor use. Plus, we offer competitive pricing and flexible order quantities to cater to your specific needs. Whether you’re in manufacturing, construction, or another industry, I’m confident that our OEM stainless steel bolts can help enhance your operations. Don’t settle for less when it comes to quality—opt for products that deliver outstanding performance and durability. Let’s connect and find the right solutions for you!

Oem Stainless Steel Bolt Application Where Service Meets Innovation

In the fast-evolving world of manufacturing, innovative solutions are crucial for meeting the diverse needs of global buyers. One area where technological advancements have a significant impact is in the production of OEM stainless steel bolts. These fasteners are integral to numerous applications across various industries, from automotive to construction. Their strength, corrosion resistance, and adaptability make them a preferred choice for manufacturers looking to achieve durability and reliability in their products. The beauty of customizing stainless steel bolts lies in the ability to cater specifically to the unique requirements of each client. This means not only producing varying sizes and grades of bolts but also developing specialized coatings or finishes that enhance performance in specific environments. By embracing innovation in design and production, manufacturers can ensure that they meet the intricate demands of a global market where quality standards are continually rising. Ultimately, the fusion of service excellence and innovative technology creates a robust framework for success. By prioritizing customer needs and harnessing the latest advancements in materials and manufacturing processes, suppliers can deliver tailored solutions that not only fulfill immediate requirements but also pave the way for future collaborations. For global buyers, partnering with forward-thinking manufacturers ensures access to top-notch products that drive efficiency and enhance overall operational performance.

Oem Stainless Steel Bolt Application Where Service Meets Innovation

| Application Area | Material Grade | Size (mm) | Corrosion Resistance | Temperature Range (°C) |

|---|---|---|---|---|

| Automotive | A2-70 | M8 | High | -40 to 120 |

| Construction | A4-80 | M10 | Very High | -40 to 200 |

| Marine | A4-50 | M12 | Medium | -10 to 70 |

| Aerospace | A2-80 | M6 | High | -50 to 150 |

| Food Industry | A4-70 | M5 | High | 0 to 100 |

Related Products