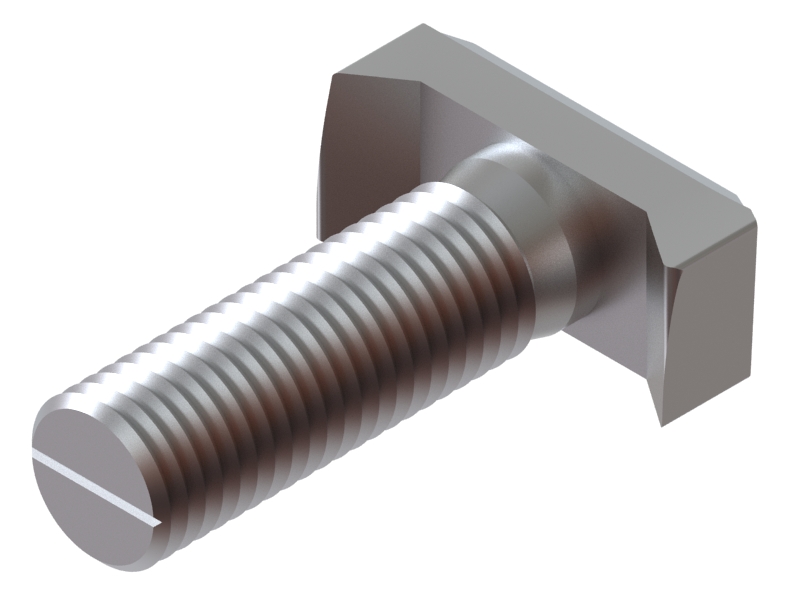

Mushroom Head Bolt: Reliable Quality for Your DIY Projects & Repairs

When I search for high-quality fasteners, I always keep an eye out for Mushroom Head Bolt. These bolts offer a unique blend of strength and versatility, making them perfect for a variety of industrial applications. With a broad, mushroom-shaped head, they provide superior load distribution and resist stripping. Whether you're enhancing machinery, constructing frameworks, or requiring reliable components for assembly, these bolts are a great choice. Clients often tell me how impressed they are by the durability and consistency of my Mushroom Head Bolts—they really simplify their projects. If you're focused on finding dependable, long-lasting fasteners, look no further. Let’s connect and discuss how my Mushroom Head Bolts can meet your specific needs.

Mushroon Head Bolt Service Sets the Industry Standard

In an ever-evolving market, the demand for high-quality, reliable components is at an all-time high. The introduction of mushroom head bolt service sets has revolutionized the industry, providing a robust solution for a variety of applications. These specialized bolts not only enhance efficiency and safety but also significantly reduce maintenance costs over time. They are designed to withstand stress, pressure, and environmental factors, making them ideal for both industrial and commercial uses. What sets these mushroom head bolts apart from traditional options is their unique design and manufacturing process. The mushroom shape allows for increased load distribution and better grip, ensuring that the bolts remain securely fastened even under extreme conditions. This innovative approach not only meets but exceeds international quality standards, providing peace of mind for global buyers who prioritize quality and performance in their sourcing decisions. For procurement professionals seeking dependable partners and superior products, investing in mushroom head bolt service sets is a smart choice. These components not only facilitate seamless operations but also enhance overall project efficacy. As industries demand more sustainable and cost-effective solutions, embracing such advancements will undoubtedly provide a competitive edge. Explore the benefits of incorporating these industry-standard components into your operations and ensure your projects are built on a foundation of quality and reliability.

Mushroom Head Bolt Service Sets the Industry Standard

| Dimension | Material | Coating | Load Capacity (lbs) | Application Area |

|---|---|---|---|---|

| M8 x 1.25 x 40mm | Steel | Zinc Plated | 1500 | Automotive |

| M10 x 1.5 x 50mm | Stainless Steel | Polished | 2000 | Industrial Machinery |

| M12 x 1.75 x 60mm | Aluminum | Anodized | 1800 | Construction |

| M16 x 2.0 x 70mm | Alloy Steel | Black Oxide | 2500 | Aerospace |

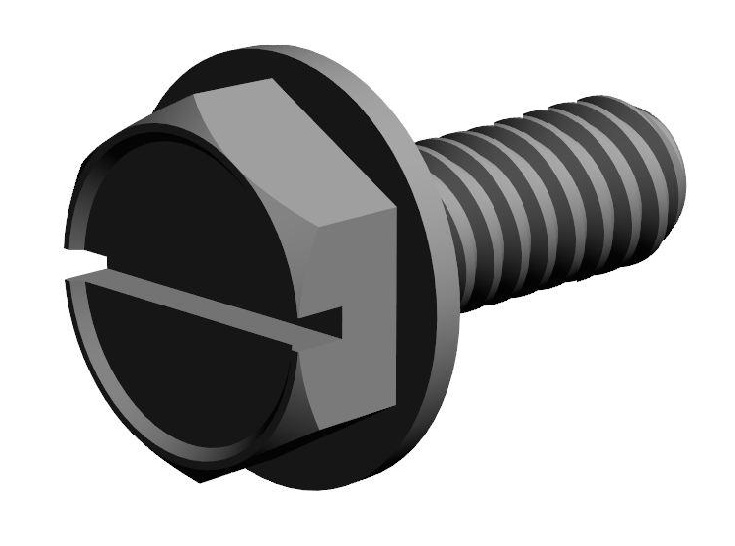

Related Products