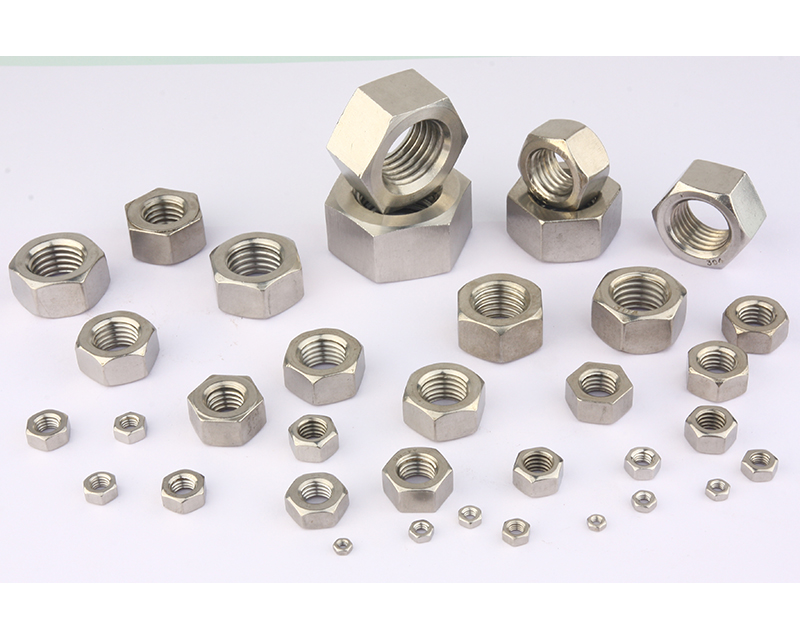

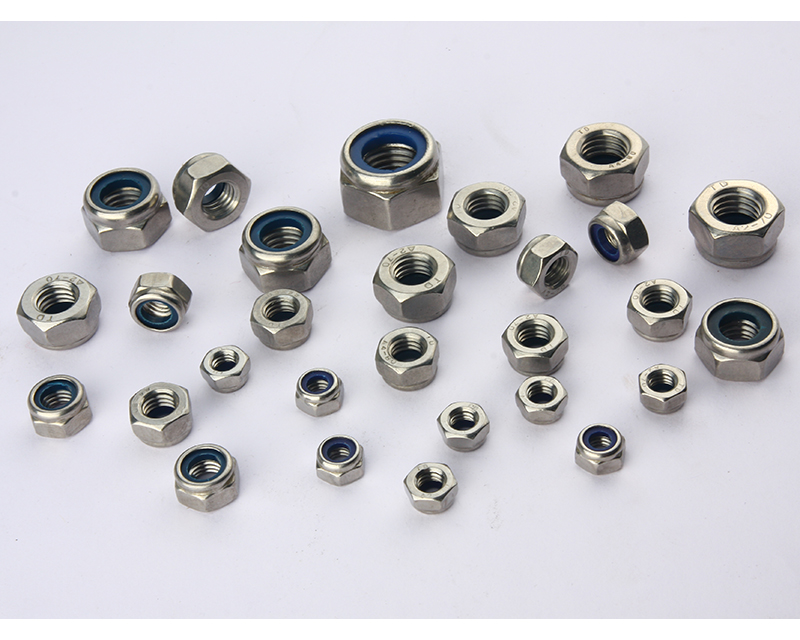

Hexagon Full Nut: Durable Fasteners for Your Project Needs

As a business owner, I've found that quality and reliability are crucial when selecting hardware components. That's why I turn to the Hexagon full nut. This product not only provides superior grip but also ensures a tight fit, minimizing the risk of loosening in high-vibration environments. I appreciate how these nuts are designed for easy installation and compatibility with various bolt sizes, making it a versatile choice for any project. When sourcing these Hexagon full nuts, I've noticed they come in various materials and finishes, so I can choose what best fits my needs. The durability of the nuts means less time spent on replacements, which is a significant cost-saver in the long run. If you’re a B2B purchaser looking for dependable fasteners that perform under pressure, the Hexagon full nut is the go-to option! Let’s talk about how this can enhance your assembly processes.

Hexagon full nut in 2025 Where Service Meets Innovation

In 2025, the landscape of the fastener industry is poised for transformation, particularly with the rising demand for hexagon full nuts. As procurement professionals look for reliable components that blend quality and innovation, understanding the evolution of hexagon full nuts becomes crucial. These essential fasteners not only play a pivotal role in various applications, from construction to machinery, but they also represent a fusion of engineering precision and cutting-edge technology. The future of hexagon full nuts is characterized by advancements in materials and manufacturing processes. Eco-friendliness and sustainability are now at the forefront of production, responding to global calls for greener solutions. Moreover, innovation in design ensures that these nuts meet more stringent safety standards and performance requirements, enhancing their reliability across diverse industries. Global buyers can expect a new wave of hexagon full nuts that not only meet existing specifications but also exceed expectations in terms of durability and function. As we approach 2025, fostering strong supplier relationships will be more important than ever. By partnering with manufacturers who prioritize innovation and service, procurement professionals can ensure they are well-equipped to adapt to market shifts and consumer demands. The intersection of exceptional service and groundbreaking innovation in the hexagon full nut sector holds significant promise, paving the way for enhanced operational efficiency and product performance in global markets.

Hexagon Full Nut in 2025: Where Service Meets Innovation

| Dimension (mm) | Material | Coating | Application | Innovation Feature |

|---|---|---|---|---|

| M12 | Carbon Steel | Zinc Plated | Automotive | Self-Locking Mechanism |

| M16 | Stainless Steel | Black Oxide | Construction | Corrosion Resistance |

| M20 | Alloy Steel | Hot-Dip Galvanized | Heavy Machinery | High Load Capacity |

| M24 | Titanium | None | Aerospace | Lightweight Strength |

Related Products