Hex Weld Nut: Quality Fasteners for Your Project Needs & Applications

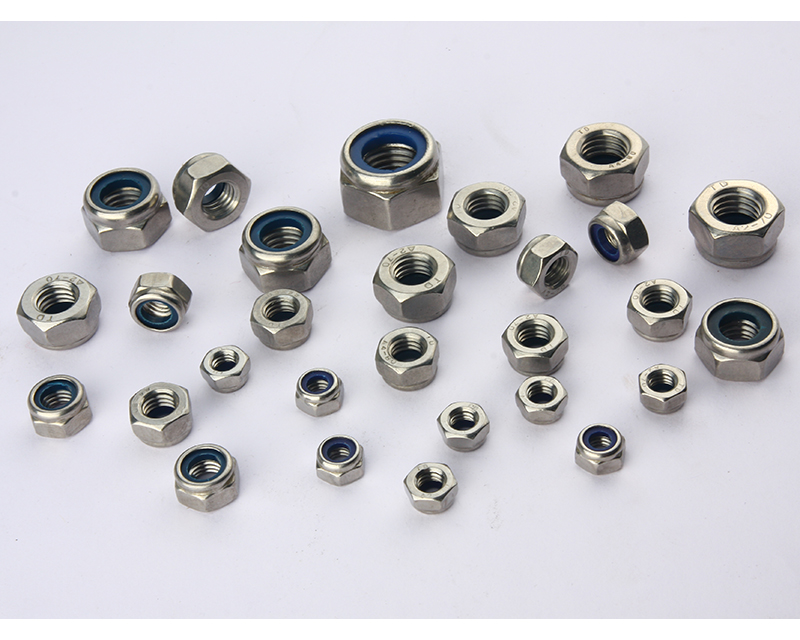

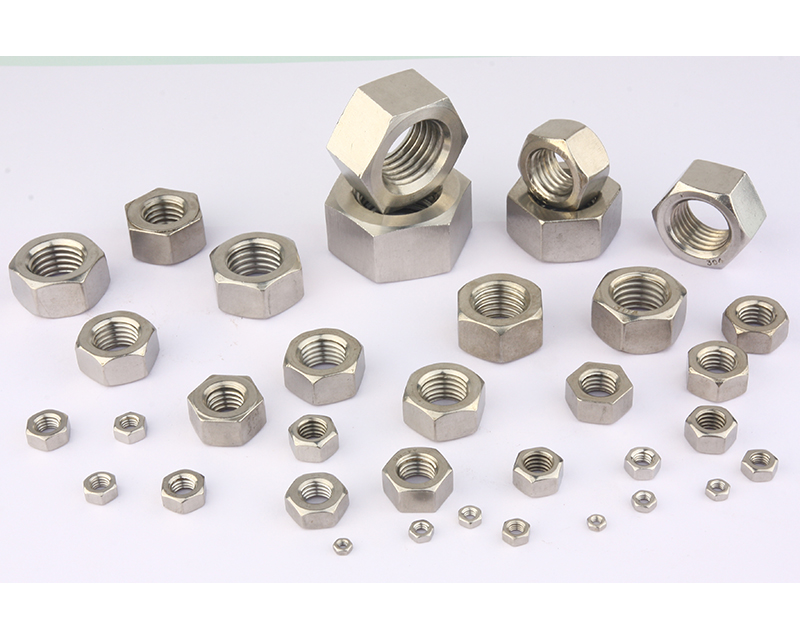

When it comes to reliable fastening solutions, I often turn to Hex Weld Nuts. These components offer exceptional strength and versatility, making them ideal for various applications. I’ve found that their hexagonal shape allows for easy alignment and secure welding, ensuring durability under stress. Whether you’re involved in automotive manufacturing, construction, or heavy machinery, using quality hex weld nuts can significantly enhance your assembly process. I appreciate that they cater to high-volume production needs while maintaining precision. With features like corrosion resistance and a robust construction, these nuts are designed to last. If you’re aiming to reduce downtime and improve overall efficiency in your projects, integrating hex weld nuts into your supply chain can make a real difference. Trust me, once you experience their performance, you’ll understand why they’re a top choice for B2B purchasers like us.

Hex Weld Nut Dominates Service Backed by Expertise

In the ever-evolving landscape of manufacturing, the hex weld nut stands out as a key component, known for its durability and effectiveness in various applications. With advancing technology and rigorous quality control processes, companies specializing in hardware production are committed to delivering products that meet international standards. This dedication ensures that the hex weld nut is not just another item on a procurement list, but a critical element that enhances the performance and longevity of assemblies in diverse sectors. Backing the innovation and quality of the hex weld nut is a wealth of expertise that shapes its design and functionality. Manufacturers leverage extensive experience and technical knowledge to refine their offerings, ensuring every hex weld nut is fabricated with precision to withstand demanding operational environments. Global purchasers can trust that these products are engineered to deliver consistent performance, ultimately leading to improved productivity and reduced maintenance costs in their operations. Choosing the right supplier for hex weld nuts is essential for procurement professionals seeking reliability and efficiency. A supplier's commitment to customer service and responsive solutions complements their product offerings, providing peace of mind and fostering long-term partnerships. By aligning with experts in the industry, procurement teams can ensure they source components that not only meet their technical requirements but also contribute to their overall success.

Hex Weld Nut Dominates Service Backed by Expertise

| Dimension | Material | Finish | Load Capacity (lbs) | Application |

|---|---|---|---|---|

| 1/4" x 20 | Steel | Zinc Plated | 700 | Automotive |

| 5/16" x 18 | Stainless Steel | Passivated | 1000 | Construction |

| 3/8" x 16 | Carbon Steel | Black Oxide | 1500 | Heavy Machinery |

| 1/2" x 13 | Alloy Steel | Galvanized | 2000 | Industrial Applications |

Related Products