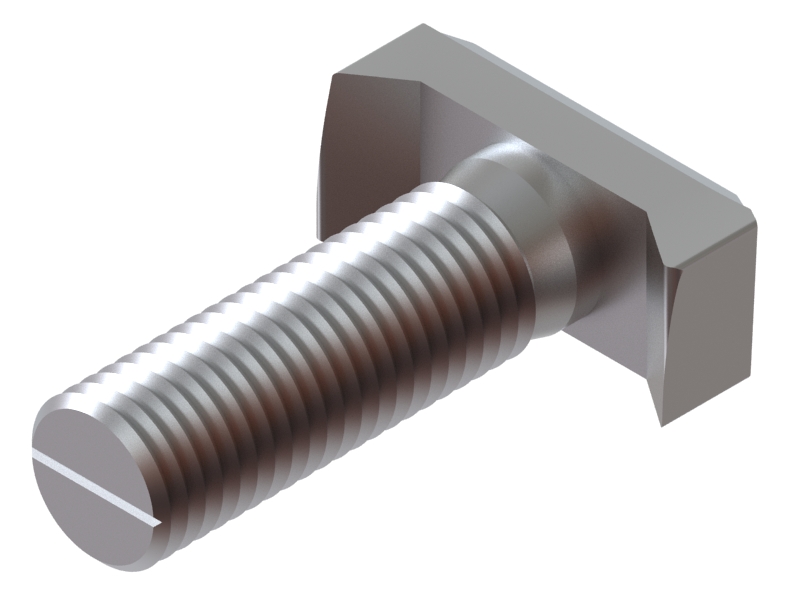

Galvanized Hex Bolt - Durable Fasteners for Reliable Applications

When it comes to sourcing reliable fasteners, I often turn to galvanized hex bolts for their durability and corrosion resistance. These bolts are perfect for a wide range of applications, from construction projects to machinery assembly. Not only do they offer exceptional strength, but their hot-dipped galvanization gives them an added layer of protection against rust and wear, making them ideal for outdoor or industrial use. Whether I'm working with steel structures or wooden frameworks, I appreciate how easily these bolts can be installed, thanks to their hexagonal heads that allow for secure torque. Plus, I find their availability in various sizes makes it easy to find exactly what I need for every job. If you’re seeking high-quality galvanized hex bolts, you can trust in our product range—we prioritize quality and effectiveness, ensuring your projects hold up under pressure.

Galvanized Hex Bolt Application Dominates

Galvanized hex bolts have become a cornerstone in various industries, given their strength and resistance to corrosion. These fasteners are ideal for applications where durability is paramount, making them a preferred choice in construction, automotive, and manufacturing sectors. The unique coating process that results in galvanization enhances the longevity of hex bolts, allowing them to withstand harsh environmental conditions, from coastal areas with salty air to regions with heavy rainfall. The versatility of galvanized hex bolts extends beyond mere functionality; they facilitate easier and faster installation while providing a reliable connection. This has led to their increasing adoption across global supply chains, where efficiency and reliability are crucial. With an ever-growing demand for sustainable and high-quality fasteners, galvanized hex bolts have established themselves as an optimal solution, promoting seamless integration into various construction and manufacturing processes. Procurement professionals seeking durable and dependable fasteners will find that investing in galvanized hex bolts not only meets their immediate project needs but also contributes to long-term operational efficiency. As industries continue to evolve, the application of galvanized hex bolts is likely to expand, reinforcing their status as essential components in assembling robust structural solutions worldwide.

Galvanized Hex Bolt Application Dominates

| Application Area | Material Type | Bolt Diameter (mm) | Coating Type | Common Uses |

|---|---|---|---|---|

| Construction | Carbon Steel | 10 | Zinc Coated | Structural Framing |

| Automotive | Alloy Steel | 12 | Hot Dipped Galvanized | Chassis Components |

| Manufacturing | Stainless Steel | 14 | Electro Galvanized | Machine Assembly |

| Marine | Marine Grade Steel | 16 | Galvanic Coating | Boat Assembly |

| Construction Equipment | Cold Rolled Steel | 18 | Zinc Plated | Heavy Machinery |

Related Products