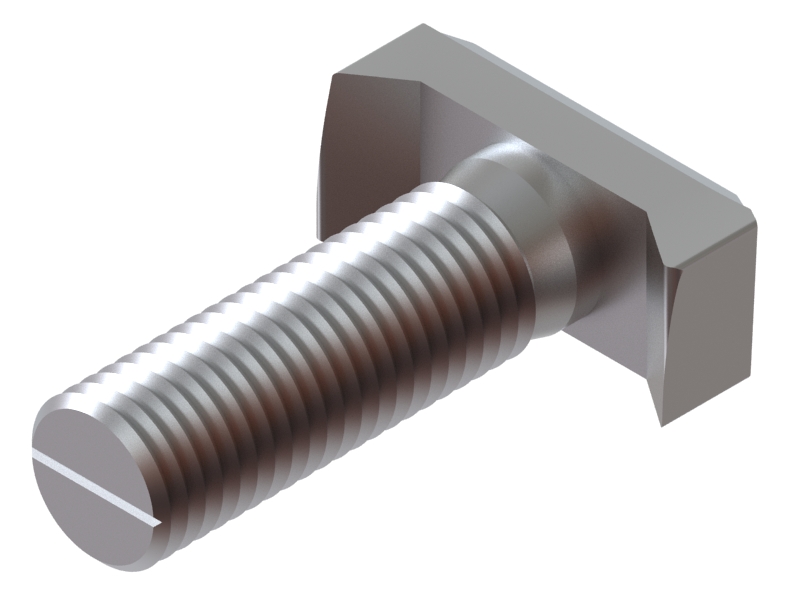

Galvanized Carriage Bolt - Durable Fasteners for Reliable Construction

When I first started sourcing fasteners, I quickly realized the importance of choosing the right ones for my projects. That's where galvanized carriage bolts come into play. These bolts are not just durable; they’re designed to withstand harsh environments thanks to their rust-resistant coating. If you're like me, you understand that quality matters, especially when you aim for long-lasting results in your constructions. Whether you need a sturdy solution for woodworking or structural applications, galvanized carriage bolts provide that strength and reliability. I've found they’re perfect for heavy-load projects. Plus, their smooth, rounded heads give a clean finish, making them ideal for visible installations. It's all about making choices that contribute to a successful outcome. If you're aiming to elevate your project’s integrity, these bolts are a game-changer. Let's connect and explore how these can fit your business needs.

Galvanized Carriage Bolt Sets the Industry Standard Supplies the World\u2019s Top Brands

In the hardware industry, the importance of quality and reliability cannot be overstated, especially when it comes to essential components like galvanized carriage bolts. These fasteners play a critical role in construction and assembly, providing the strength and durability necessary to withstand various environmental conditions. By setting the industry standard in galvanized carriage bolts, manufacturers are able to supply some of the world’s top brands, ensuring that projects are completed with the highest level of performance and safety. Galvanized carriage bolt sets are designed to offer superior resistance to rust, corrosion, and wear. This makes them particularly appealing for industries ranging from construction to automotive, where exposure to harsh conditions is a daily reality. The precision engineering used in the production of these bolts ensures a perfect fit and reliable functionality, which ultimately translates into enhanced efficiency for procurement managers and project leaders. Furthermore, as sustainability becomes a key consideration in sourcing, the long lifespan of galvanized fasteners positions them as an eco-friendly choice that can help reduce waste over time. By choosing high-quality galvanized carriage bolts, global buyers can not only guarantee the integrity of their projects but also strengthen their supply chains with trusted products. As the demand for dependable fasteners continues to grow, partnering with industry leaders can provide procurement professionals with a competitive edge in delivering superior products that meet strict international standards. Investing in top-tier fastening solutions is not just a choice—it's a commitment to excellence that resonates throughout the supply chain.

Galvanized Carriage Bolt Sets the Industry Standard Supplies the World’s Top Brands

| Dimension | Material | Coating Type | Finish | Standard | Application |

|---|---|---|---|---|---|

| 1/4" x 2" | Carbon Steel | Galvanized | Zinc Plated | ASTM A307 | Construction |

| 5/16" x 3" | Alloy Steel | Hot-Dipped Galvanized | Smooth | ASTM A325 | Heavy Machinery |

| 3/8" x 4" | Stainless Steel | Electro-Galvanized | Brushed | AISC | Marine Applications |

| 1/2" x 5" | Boron Steel | Dacromet Coated | Matte | ISO 898-1 | Automotive Industry |

Related Products