DIN 5299: Essential Information for Quality Hardware Selection

When I'm in need of reliable fastening solutions, I always turn to DIN 5299. These high-quality retaining rings are essential for securely holding components in place, ensuring everything stays intact under pressure. Whether I'm working on machinery or in automotive applications, the precision and durability of DIN 5299 give me peace of mind. I appreciate how easy they are to install, making my workflow more efficient. Plus, the availability of various sizes means I can find the perfect fit for any project. If you’re searching for a sturdy and dependable solution to enhance your product assembly, consider adding DIN 5299 to your toolkit. The performance and reliability make it a must-have for any B2B business. With my experience, I can confidently say that these rings not only meet industry standards but exceed them—providing exceptional value for money. Trust me, when it comes down to quality, DIN 5299 has got you covered.

DIN 5299 Guarantees Peak Performance Where Service Meets Innovation

In the world of hardware solutions, achieving peak performance requires a harmonious blend of reliability and innovation. The DIN 5299 standard exemplifies this synergy, offering a robust framework for manufacturers aiming to deliver high-quality products that meet the evolving needs of global industries. As businesses seek to enhance their operational efficiency and ensure safety in various applications, adopting standards like DIN 5299 becomes paramount. This not only simplifies compliance but also assures purchasers of the product’s durability and functionality, a significant consideration for those in the procurement process. Products conforming to this standard provide a level of assurance that speaks to both quality and performance. They play a critical role in applications ranging from construction to automotive, where precision and safety are non-negotiable. Procurement professionals searching for cutting-edge solutions will find that embracing innovations in DIN 5299 components can lead to significant improvements in overall system performance. By integrating advanced materials and design techniques, manufacturers are able to push the boundaries of what’s possible, ensuring that customers receive not just products, but lifelong partnerships built on superior service and trust. As the global marketplace becomes increasingly competitive, the demand for innovative hardware solutions is surging. Procurement teams that prioritize such standards in their purchasing strategies will not only enhance their supply chain resilience but also gain a competitive edge. By focusing on quality-driven products that adhere to rigorous specifications, businesses can ensure they are well-prepared to meet the challenges of today and tomorrow, paving the way for success in an ever-evolving industry landscape.

DIN 5299 Guarantees Peak Performance Where Service Meets Innovation

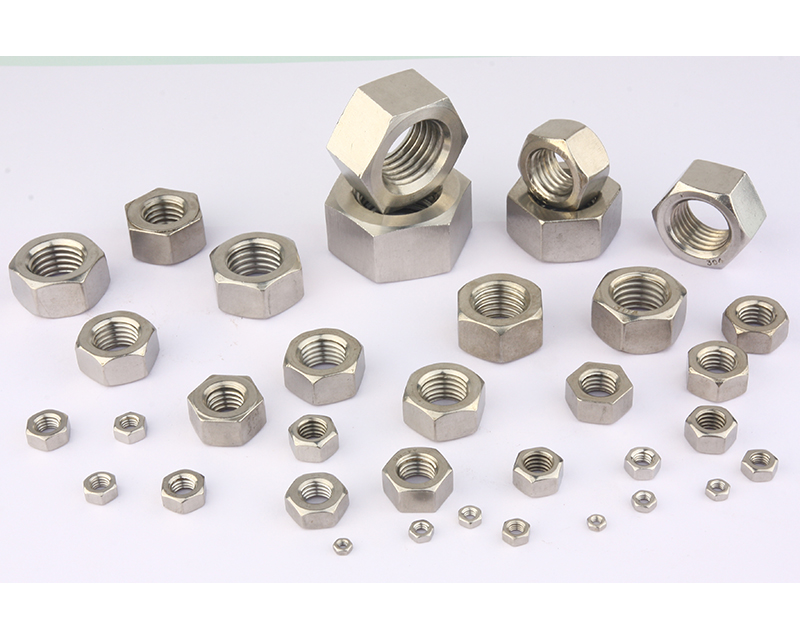

| Dimension | Material | Coating Type | Applications | Certification |

|---|---|---|---|---|

| 5mm | Stainless Steel | Zinc Plated | Automotive, Industrial | ISO 9001 |

| 6mm | Carbon Steel | Hot Dip Galvanized | Construction, Heavy Machinery | ASTM A36 |

| 8mm | Alloy Steel | Phosphate Coated | Oil & Gas, Aviation | MIL-STD-648 |

| 10mm | Titanium | Anodized | Medical, Aerospace | AS9100 |

Related Products