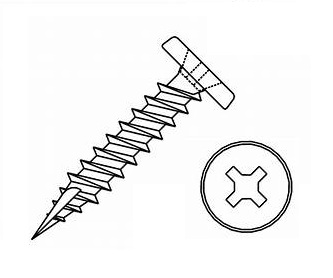

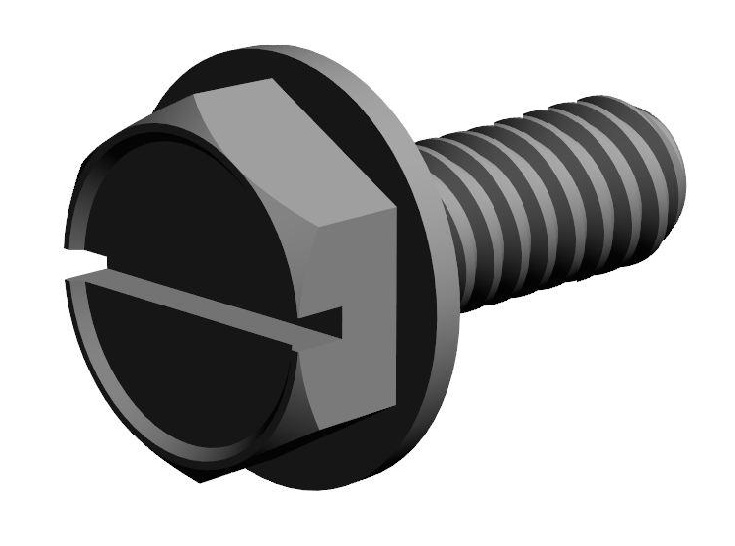

Custom Resistance Screws for Optimal Performance and Reliable Solutions

When it comes to precision and reliability, I trust our Custom Resistance Screws to meet my toughest demands. These screws are designed specifically to provide superior resistance in various applications, ensuring they hold up under pressure. I know how important it is for B2B purchasers like me to find high-quality components that are not only durable but also tailored to specific needs. With our Custom Resistance Screws, I can choose the dimensions and materials that perfectly align with my project requirements. Moreover, the ordering process is seamless, allowing for bulk purchases that save time and money. Whether I need them for machinery, electronics, or any other use, I appreciate the fact that these screws are built to last. The attention to detail and customizable options give me peace of mind, knowing I’m investing in the best for my business. Don't settle for standard—elevate your projects with our Custom Resistance Screws and experience the difference yourself.

Custom Resistance Screw Service Dominates

In today's highly competitive landscape, custom solutions play a vital role in meeting unique client needs, and resistance screws are no exception. Our expertly engineered custom resistance screws are designed to withstand the most demanding conditions, providing exceptional durability and reliability. This specialization is crucial for industries ranging from automotive to construction, where traditional fasteners might fail under pressure. By focused innovation and precision manufacturing, we deliver products that not only meet but exceed industry standards. Global buyers are increasingly seeking partnerships with manufacturers that can guarantee consistent quality and performance. Our commitment to rigorous quality control and state-of-the-art production techniques ensures that every custom resistance screw is crafted to perfection. We understand that each project has specific requirements, which is why we offer tailored solutions to support our clients' diverse applications. This customer-centric approach not only enhances project efficiency but also contributes to long-term satisfaction. In an era where adaptability and precision are paramount, our custom resistance screw services are uniquely positioned to lead the market. Collaborating with us means accessing expert knowledge and innovative solutions that align with your business goals. Join the growing number of industries that trust custom-engineered products to drive their success and unlock new opportunities for innovation in your operations.

Custom Resistance Screw Service Dominates

| Application | Material | Resistance Type | Diameter (mm) | Length (mm) | Coating |

|---|---|---|---|---|---|

| Automotive | Carbon Steel | Corrosion Resistant | 4.5 | 20 | Zinc Plated |

| Electronics | Stainless Steel | Heat Resistant | 3.0 | 15 | None |

| Aerospace | Titanium Alloy | High Strength | 5.0 | 25 | Anodized |

| Construction | Alloy Steel | Impact Resistant | 6.5 | 30 | Galvanized |

Related Products