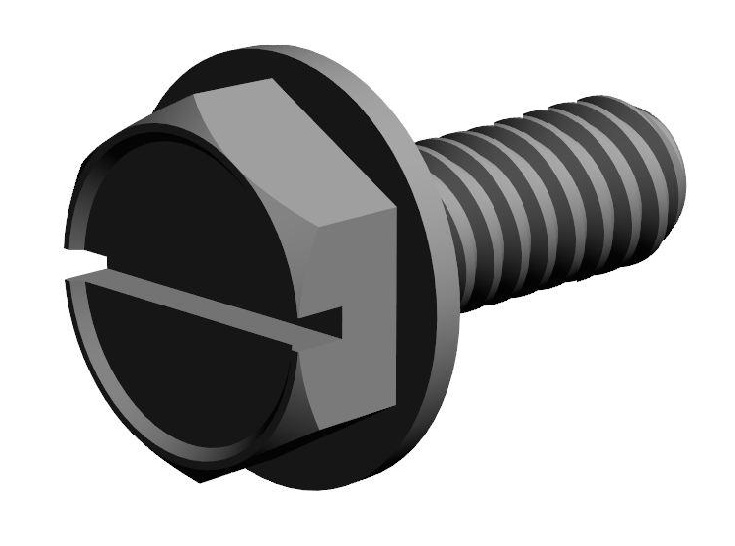

China Hex Socket Cap Screw - Top Quality Fasteners for Your Projects

As someone who often navigates the world of industrial fasteners, I can confidently say that the China Hex Socket Cap Screw is a top contender for any B2B purchaser. These screws are crafted from high-quality materials, ensuring superior strength and durability for your projects. Whether it's for automotive, construction, or machinery applications, they deliver the reliability you need. When I search for the best suppliers, I always keep an eye out for companies that prioritize quality and customer support. Sourcing from trusted manufacturers in China, you're tapping into a market known for both innovation and competitive pricing. If you’re aiming for efficiency in your assembly processes, these hex socket cap screws won’t disappoint. They offer precise fitting and easy installation, making them perfect for those who value quality without compromising on time. So, for your next project, consider using our high-performance screws to elevate your productivity!

China Hex Socket Cap Screw Factory Your Trusted OEM Partner

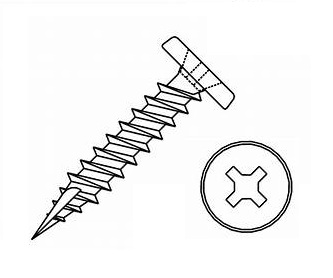

When it comes to sourcing high-quality hex socket cap screws, partnering with a reliable factory is essential for global buyers. A trustworthy OEM partner not only ensures consistent quality but also provides the flexibility to meet unique product specifications. In these competitive times, manufacturers must leverage advanced technology and maintain rigorous quality control standards to fulfill the demanding needs of international markets. The manufacturing process involves meticulous attention to detail, from selecting premium raw materials to precision machining and finishing. This commitment to excellence guarantees that each hex socket cap screw meets industry standards and customer expectations. Additionally, strategic partnerships with suppliers and robust supply chain management help in delivering products swiftly and efficiently, ensuring that your production schedules remain uninterrupted. As companies increasingly seek sustainable manufacturing practices, a focus on environmentally conscious processes and responsible sourcing has become paramount. By choosing an OEM partner that prioritizes sustainability, global buyers can not only enhance their product offerings but also contribute to a greener future. By working collaboratively with a dedicated factory, businesses can achieve their operational goals while having the peace of mind that they are supported by an experienced and committed partner.

China Hex Socket Cap Screw Factory Your Trusted OEM Partner

| Material | Diameter (mm) | Length (mm) | Surface Treatment | Application | Certification |

|---|---|---|---|---|---|

| Carbon Steel | 8 | 20 | Zinc Plated | Automotive | ISO 9001 |

| Stainless Steel | 10 | 25 | Passivation | Marine | ASTM |

| Alloy Steel | 12 | 30 | Black Oxide | Construction | CE |

| Titanium | 6 | 15 | Anodized | Aerospace | AS9100 |

| Brass | 5 | 10 | Natural | Electronics | RoHS |

Related Products