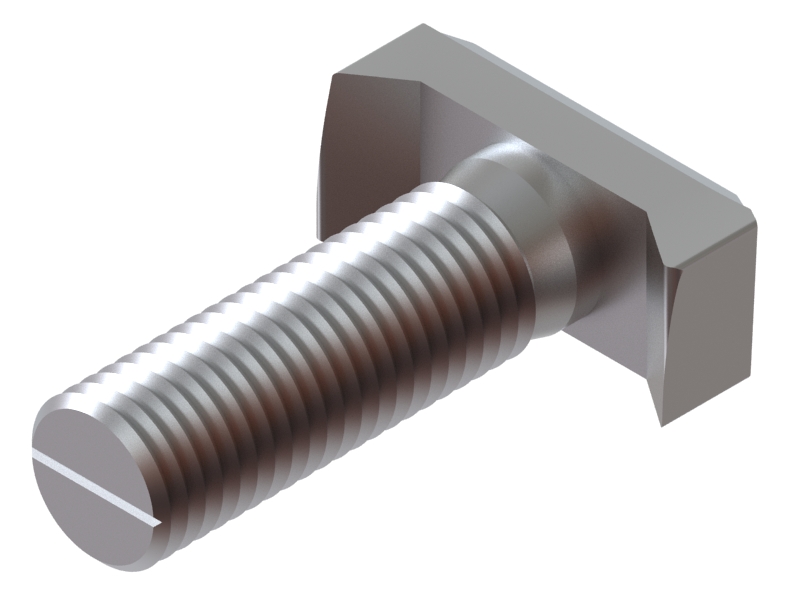

316 Carriage Bolt: Durable Fasteners for Reliable Construction Projects

When I first came across the 316 Carriage Bolt, I knew it was the perfect choice for my projects. This premium stainless steel bolt offers exceptional corrosion resistance, making it ideal for both marine and outdoor applications. Its unique design features a rounded head, allowing for a clean aesthetic while providing reliable fastening strength. I found it incredibly versatile—perfect for wood and metal connections alike. With its sturdy build, I never have to worry about it loosening, even under heavy loads. Whether I’m working on constructions that require durability or looking to secure parts that demand strength, this bolt stands out. Plus, ordering in bulk made it easy to keep my inventory stocked. If you're aiming to enhance your projects with quality fasteners, the 316 Carriage Bolt is definitely worth considering. You can trust it to deliver the performance and reliability you need for your business.

316 Carriage Bolt Industry Giant Sets the Industry Standard

In the competitive landscape of the hardware industry, the introduction of the 316 carriage bolt has revolutionized fastening solutions, setting an industry benchmark for quality and durability. These robust fasteners, crafted from premium stainless steel, boast exceptional corrosion resistance, making them ideal for use in marine, construction, and outdoor applications where environmental factors can take a toll on hardware longevity. With a growing emphasis on sustainability and reliability, the demand for high-quality carriage bolts has surged, attracting global procurement buyers looking for dependable solutions. The 316 carriage bolt is not just about strength; it embodies the perfect balance of functionality and aesthetics. Designed for easy installation, these bolts provide a seamless finish that enhances the visual appeal of any project. The uniformity in dimensions and the high precision in manufacturing processes ensure that each bolt meets rigorous standards, instilling confidence in procurement professionals who seek to minimize risks associated with material failure. By choosing 316 carriage bolts, buyers can leverage the industry's finest standards, optimizing their supply chains while securing long-term performance for their applications. As market trends shift towards innovation and quality, procurement teams are encouraged to partner with manufacturers that prioritize cutting-edge technology and sustainable practices. By investing in superior-grade carriage bolts, businesses can not only delight their customers with enhanced product offerings but also position themselves as leaders in reliability and excellence within the market. Making informed sourcing decisions today will pave the way for greater operational efficiency and success in the dynamic global marketplace.

316 Carriage Bolt Industry Giant Sets the Industry Standard

| Dimension (mm) | Material Type | Coating Type | Strength Grade | Applications |

|---|---|---|---|---|

| 8 x 50 | 316 Stainless Steel | None | 70,000 PSI | Marine, Automotive |

| 10 x 60 | 316 Stainless Steel | Electropolished | 80,000 PSI | Construction, Industrial |

| 12 x 75 | 316 Stainless Steel | Hot-Dipped Galvanized | 70,000 PSI | Agricultural, Marine |

| 14 x 100 | 316 Stainless Steel | None | 80,000 PSI | Heavy Equipment, Structural |

| 16 x 120 | 316 Stainless Steel | Passivated | 90,000 PSI | Aerospace, Military |

Related Products