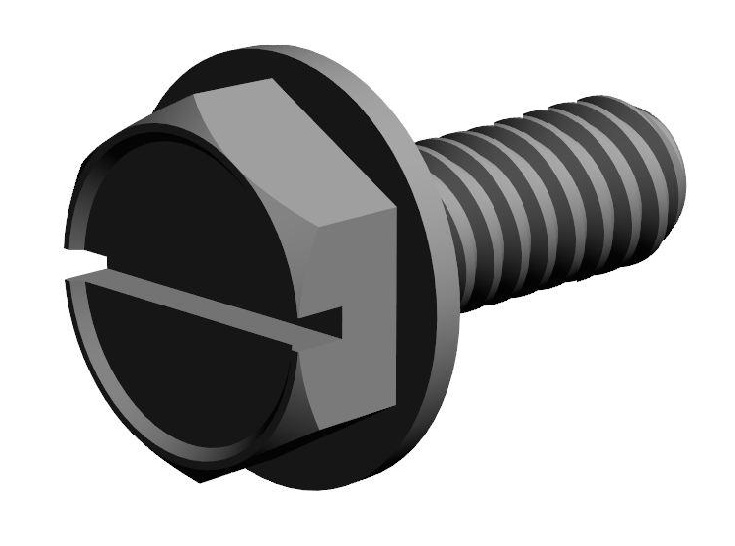

High-Quality Taiwan Screw: Durable Choices for Your Projects and Needs

When I think about precision and reliability in fasteners, Taiwan Screw stands out in my mind. These screws are meticulously manufactured, ensuring they meet the highest standards of quality. Whether you're in construction, automotive, or electronics, I'm sure you'll appreciate how these screws deliver durability and strength for your projects. I've seen buyers just like you searching for dependable suppliers who understand the importance of timely delivery and excellent customer support. That's what you can expect when choosing Taiwan Screw. Our screws come in various sizes and types, making them versatile for different applications. With competitive pricing and a commitment to innovation, joining our list of satisfied customers is just a step away. Reach out today, and let's discuss how Taiwan Screw can meet your fastening needs and elevate the quality of your projects!

Taiwan Screw Delivers Unmatched Quality Where Innovation Meets 2025

In an era where precision and quality are paramount in the manufacturing sector, the screw industry stands at the forefront of innovation. As we approach 2025, the demand for high-performance screws tailored to diverse applications has never been greater. This is a reflection of evolving industrial needs that require not only durability but also versatility. The future of fastening solutions lies in the ability to blend traditional craftsmanship with modern technology, ensuring that products meet the rigorous standards set by global markets. With an unwavering commitment to excellence, leading manufacturers are embracing advanced manufacturing processes and cutting-edge materials. This fusion of innovation and quality ensures that every screw produced not only meets but exceeds international standards. Global buyers are increasingly prioritizing suppliers that deliver consistent performance and reliability, recognizing that the right fastening solution is integral to the success of their projects. As we move forward, the emphasis on sustainability and eco-friendly practices will also shape purchasing decisions, making it imperative for suppliers to adapt to these new demands. As the market evolves, staying ahead of trends and understanding buyer needs will be essential for suppliers aiming to establish long-term relationships with global purchasers. Investing in research and development, alongside adopting smart technologies, will drive competitiveness in this dynamic sector. By focusing on creating value through unmatched quality and innovative solutions, manufacturers can position themselves as key players in the global marketplace, ready to meet the needs of tomorrow's industries.

{ Taiwan Screw Delivers Unmatched Quality Where Innovation Meets 2025 }

| Material | Diameter (mm) | Length (mm) | Thread Type | Coating | Application |

|---|---|---|---|---|---|

| Stainless Steel | 4 | 50 | Metric | None | General Purpose |

| Carbon Steel | 5 | 75 | UNC | Zinc Plated | Construction |

| Aluminum | 3 | 30 | Metric | Anodized | Aerospace |

| Brass | 6 | 25 | UNC | Nickel Plated | Plumbing |

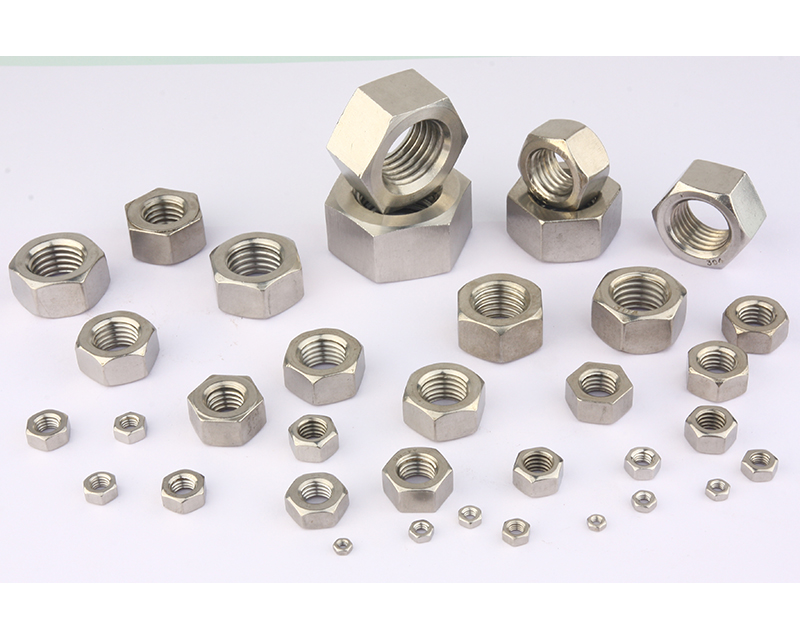

Related Products