Top Quality Stainless Weld Nuts for Reliable Performance and Durability

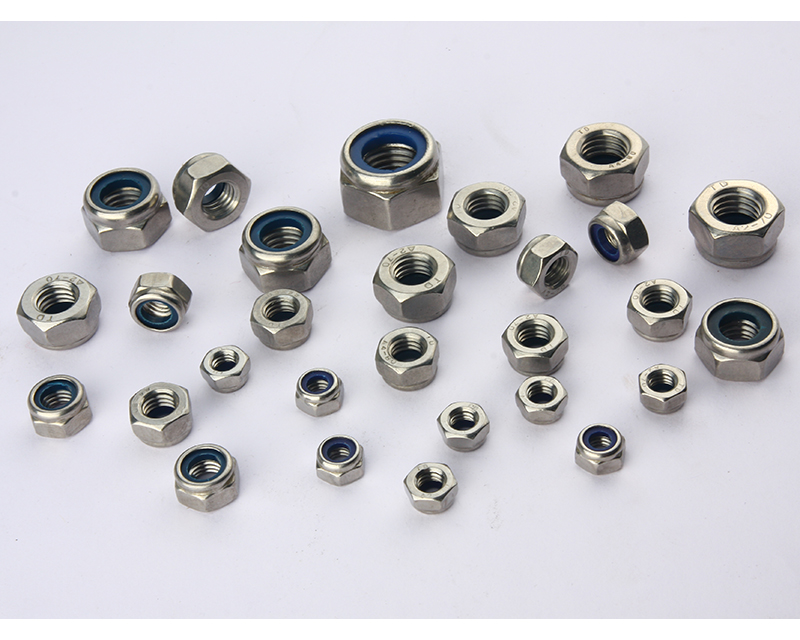

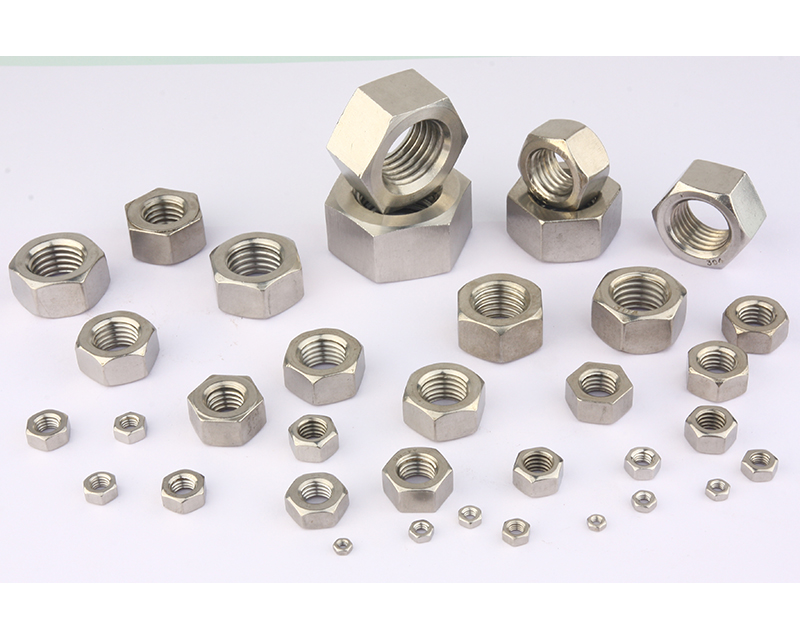

When it comes to reliable fastening solutions, I trust our Stainless Weld Nut to meet my needs for both strength and durability. Crafted from high-quality stainless steel, these weld nuts provide exceptional resistance to corrosion, ensuring a long-lasting performance even in harsh environments. I appreciate how their design allows for easy welding, making installation seamless in a variety of applications. Whether you're working on automotive projects or heavy machinery, these weld nuts offer robust support that I can depend on. Plus, their versatility makes them suitable for various industries, which is a huge plus when sourcing components for diverse projects. If you’re aiming for efficiency and reliability, choosing our Stainless Weld Nut will streamline your assembly process while providing the lasting strength you and your customers expect. Let’s partner together to elevate your manufacturing quality!

Stainless Weld Nut Stands Out Sets the Industry Standard

In the ever-evolving world of hardware solutions, stainless weld nuts have emerged as crucial components that ensure reliability and durability in various applications. Engineered with precision, these nuts feature exceptional strength and corrosion resistance, making them an ideal choice for industries ranging from automotive to construction. The innovative design of stainless weld nuts provides ease of installation, allowing manufacturers to streamline their processes and enhance overall product performance. As global procurement professionals seek high-quality components to meet stringent industry standards, the demand for stainless weld nuts has increased significantly. These nuts not only offer superior performance under harsh conditions but also contribute to the sustainability goals of modern manufacturing by reducing the need for frequent replacements. By integrating advanced material science with state-of-the-art production techniques, companies can provide products that not only meet but exceed expectations, setting new benchmarks in quality and efficiency. In conclusion, the growing preference for stainless weld nuts in various sectors highlights the industry's shift towards reliable and sustainable hardware solutions. As procurement specialists, choosing suppliers who prioritize quality and innovative technologies ensures that your projects will stand the test of time and continue to operate efficiently in today's competitive landscape. Embracing these advanced components can lead to improved product integrity and operational excellence in your manufacturing processes.

Stainless Weld Nut Stands Out Sets the Industry Standard

| Dimension (mm) | Material Grade | Finish Type | Strength (MPa) | Applications |

|---|---|---|---|---|

| 10x5 | 304 | Passivated | 520 | Automotive, Aerospace |

| 12x6 | 316 | Electropolished | 590 | Marine, Chemical Processing |

| 14x7 | 2205 | Pickled | 650 | Oil & Gas, Heavy Industry |

| 16x8 | Duplex | Bright | 700 | Pharmaceutical, Food Processing |

Related Products