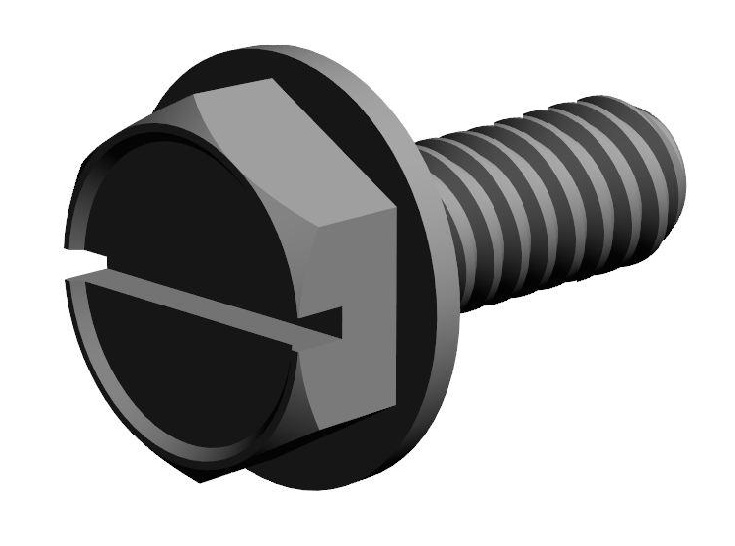

Stainless Self Tapping Screw: Durable Solutions for Your Projects

When I needed reliable fasteners for my projects, I found that Stainless Self Tapping Screws were the perfect solution. These screws not only bore into a variety of materials without pre-drilling, but their stainless steel construction ensures long-lasting durability and resistance to rust and corrosion. I noticed that they work wonders in outdoor applications and environments where moisture is a concern. As a B2B purchaser, I value quality and efficiency, and these screws definitely deliver. Whether you're assembling metal, wood, or plastic, they securely grip, providing a strong hold every time. Plus, their ease of installation saves me valuable time on the job. If you're seeking dependable performance and durability, Stainless Self Tapping Screws should be on your list. Trust me, you won’t be disappointed with the results!

Stainless Self Tapping Screw in 2025 Where Service Meets Innovation

In 2025, the landscape of fasteners is set to undergo a significant transformation, particularly for stainless self-tapping screws. These essential components are increasingly becoming the backbone of a broad spectrum of industries, from construction to electronics, thanks to their ability to provide secure and reliable connections with minimal effort. As global procurement trends lean towards innovative and sustainable solutions, stainless self-tapping screws are emerging as a key player in meeting these demands. They are not only favored for their corrosion resistance but also for their ease of installation, reducing labor costs and improving efficiency. The intersection of service and innovation will define the future of fastener supply chains. By focusing on enhancing customer service and adopting cutting-edge technologies, manufacturers are poised to offer more than just products; they will provide tailored solutions that cater to specific project needs. The integration of smart manufacturing processes and advanced logistics will ensure timely delivery and exceptional support for procurement professionals worldwide. Buyers can expect to see increased customization options, improved quality control measures, and a more transparent supply chain. As we move further into 2025, it is crucial for global buyers to align themselves with suppliers who prioritize innovation while maintaining a strong commitment to customer satisfaction. The evolving demands of the market will require a collaborative approach, where feedback loops and adaptive strategies are key. By selecting partners who embrace these principles, procurement specialists can ensure they remain competitive and responsive in an ever-changing environment. Embracing the future of stainless self-tapping screws means investing in partnerships that support both service excellence and innovative practices, paving the way for a more efficient and sustainable industry.

Stainless Self Tapping Screw in 2025 Where Service Meets Innovation

| Material | Diameter (mm) | Length (mm) | Coating Type | Application | Innovation Feature |

|---|---|---|---|---|---|

| 304 Stainless Steel | 4.0 | 30 | Zinc Plated | Construction | Self-Drilling |

| 316 Stainless Steel | 5.0 | 40 | Passivated | Marine | Corrosion Resistant |

| 410 Stainless Steel | 3.5 | 25 | Black Oxide | Automotive | Heat Treatment |

| A2 Stainless Steel | 6.0 | 50 | Bright Finish | Electronics | Non-Magnetic |

Related Products