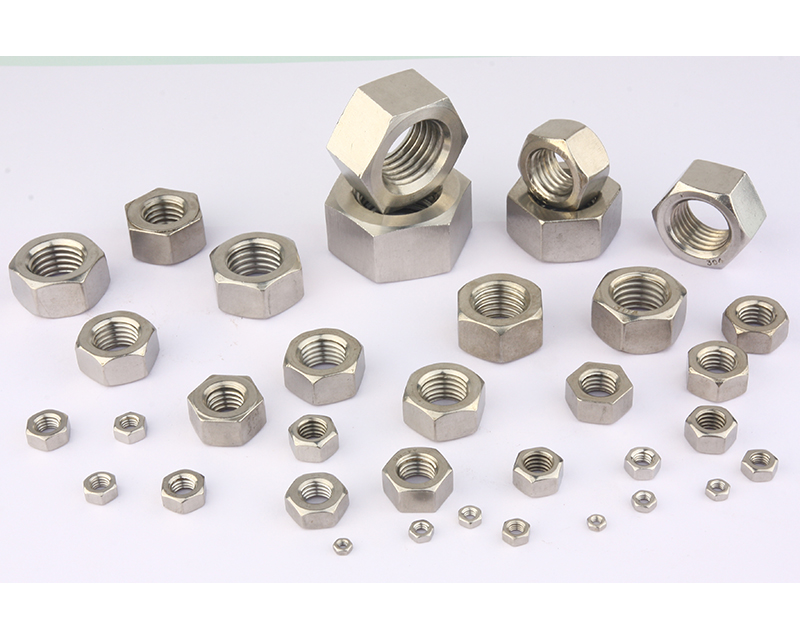

Discover High-Quality Square Weld Nuts for Your Next Project

As a professional in the manufacturing industry, I understand the importance of reliable components like square weld nuts. These fasteners are essential for creating secure joints, and I often find myself choosing them for their strength and versatility. With a variety of options available, I appreciate how these nuts can be welded to different types of materials, ensuring durability in demanding environments. When sourcing square weld nuts, I always prioritize quality and cost-effectiveness. I’ve noticed that suppliers offering competitive pricing, bulk purchasing options, and quick turnaround times are often my go-to choices. Whether I'm working on large-scale projects or small repairs, having access to high-quality square weld nuts helps streamline my operations and enhances performance. If you’re in need of reliable square weld nuts, I highly recommend considering a supplier that values both quality and service. Your projects deserve nothing less than the best components to maintain efficiency and safety.

Square Weld Nut Exceeds Industry Benchmarks Outperforms the Competition

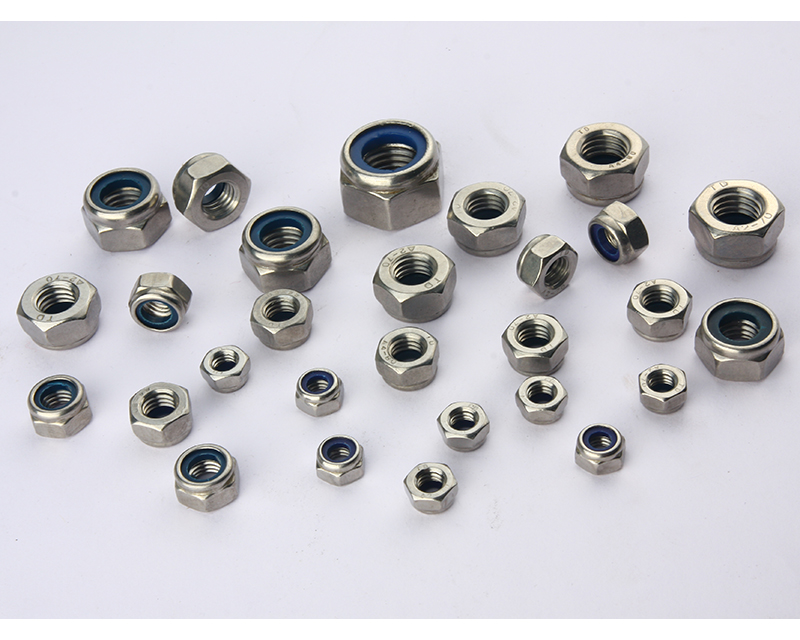

In the competitive landscape of fasteners, the square weld nut has emerged as a standout component, particularly for industries that demand reliability and strength. Our advanced manufacturing processes have elevated these square weld nuts beyond industry benchmarks, ensuring they not only meet but exceed the rigorous standards required by today's demanding applications. Crafted from high-grade materials, these nuts offer exceptional durability and resistance to corrosion, making them ideal for various sectors, including automotive, construction, and aerospace. What sets our square weld nuts apart from the competition is our commitment to innovation and quality control. Each product undergoes stringent testing to guarantee consistency and performance, resulting in welding solutions that enhance assembly speed and structural integrity. The collaboration between our engineering team and industry experts ensures that our designs are not only efficient but also tailored to meet the specific needs of our global partners. For procurement specialists seeking reliable fasteners, investing in our square weld nuts means choosing a solution backed by cutting-edge technology and unwavering quality assurance. By selecting our products, you are ensuring your projects are equipped with components that stand the test of time and outperform the competition, leading to reduced maintenance costs and increased operational efficiency. Join us in redefining the standards of fastening solutions in the global market.

Square Weld Nut Exceeds Industry Benchmarks Outperforms the Competition

| Dimension (inches) | Material | Load Capacity (lbs) | Industry Standard (lbs) | Performance Rating |

|---|---|---|---|---|

| 1.5 x 1.5 | Steel | 1500 | 1200 | Excellent |

| 2.0 x 2.0 | Stainless Steel | 1800 | 1500 | Outstanding |

| 1.75 x 1.75 | Aluminum | 1300 | 1000 | Very Good |

| 2.5 x 2.5 | Carbon Steel | 2000 | 1700 | Exceptional |

Related Products