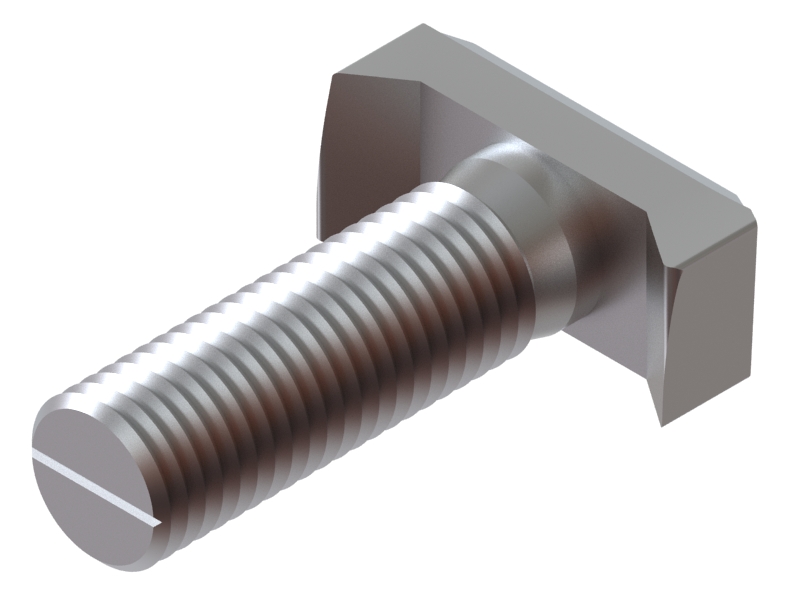

Premium Serrated Carriage Hex Bolt for Secure Fastening Solutions

When it comes to securing heavy equipment or assembling structures, I rely on the reliability of Serrated Carriage Hex Bolts. These bolts offer a superior grip and minimize loosening, ensuring that everything stays tightly fastened over time. I appreciate how their serrated design enhances friction, making them ideal for high-pressure applications where stability is crucial. Purchasing these bolts is straightforward, and I find the variety in sizes incredibly convenient, matching different project needs. With a quality finish, these bolts resist corrosion, which is essential for outdoor or industrial environments. It’s clear that using Serrated Carriage Hex Bolts can save time and labor costs due to their ease of installation and lasting durability. For any B2B buyer looking for reliable fastening solutions, these bolts provide peace of mind that parts are secure and withstand the test of usage. They really make a difference in how projects turn out, and I can't recommend them enough.

Serrated Carriage Hex Bolt Service Backed by Expertise Outperforms the Competition

In the competitive landscape of industrial fasteners, serrated carriage hex bolts have emerged as a pivotal choice for engineers and manufacturers seeking reliable and durable solutions for various applications. These specialized bolts feature a unique serrated design on their bearing surface, which provides enhanced grip and reduced slippage under torque. As a result, they ensure superior performance in critical fastening tasks, making them indispensable in fields like construction, automotive, and machinery manufacturing. The benefits of integrating serrated carriage hex bolts into your projects extend beyond their innovative design. Backed by extensive expertise in manufacturing and quality control, these bolts offer consistency and reliability that outperform competing products. Rigorous testing and adherence to international standards guarantee that our bolts withstand extreme conditions, ensuring safety and longevity. Whether you're designing a complex assembly or undertaking a large-scale construction project, choosing the right fasteners can significantly impact overall success. What sets these bolts apart is not just their functionality but also the dedicated service and knowledge that accompanies them. Understanding the unique needs of global buyers, we provide tailored solutions and expert guidance that simplify the procurement process. By focusing on quality and customer satisfaction, companies can enhance their operational efficiency and gain a competitive edge in their respective industries. Make the switch to serrated carriage hex bolts and experience the difference in performance and service.

Serrated Carriage Hex Bolt Service Backed by Expertise Outperforms the Competition

| Feature | Description | Benefit | Expert Insight |

|---|---|---|---|

| Serrated Design | Increased friction and locking capabilities. | Prevents loosening due to vibration. | Our technicians recommend serrated designs for critical applications. |

| Material Quality | High tensile strength carbon steel. | Enhanced durability and load-bearing capacity. | Experts suggest using high-strength materials for safety-critical applications. |

| Corrosion Resistance | Zinc-plated or stainless steel options. | Longevity in adverse environments. | Industry professionals recommend corrosion-resistant options for outdoor use. |

| Standard Compliance | Meets ISO and ASTM standards. | Assured quality and reliability. | Experts confirm that compliance with international standards ensures safety. |

| Versatility | Suitable for various applications. | Increases usability across different industries. | Vendors advocate for adaptable products to reduce inventory complexity. |

Related Products