Self Drilling Screw: Durable Solutions for Your DIY Projects

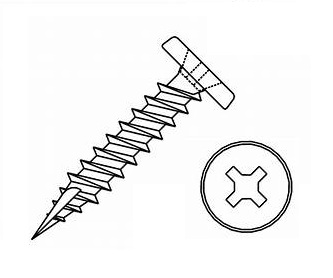

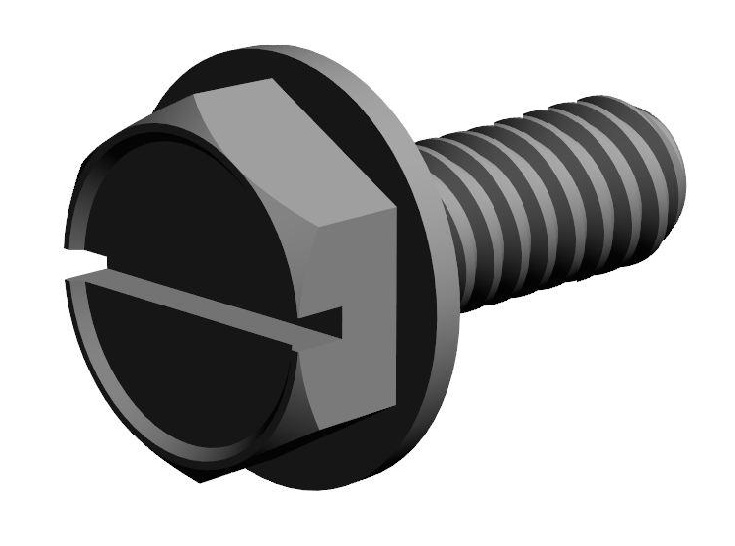

When I’m searching for reliable fasteners, self drilling screws are always a top choice for me. These screws eliminate the need for pre-drilling, saving me valuable time and effort. Designed with a sharp tip and aggressive threads, they effortlessly penetrate a variety of materials, making them ideal for construction and manufacturing applications. I love how versatile they are; whether it’s for wood, metal, or plastic, self drilling screws deliver strong holding power. Plus, their corrosion-resistant finishes ensure longevity, even in tough environments. When I consider durability and performance, these screws always meet my expectations. If you’re in the market for high-quality self drilling screws that can handle demanding projects, you’ve come to the right place. I’ve found that investing in these fasteners not only streamlines my workflow but also enhances the overall quality of my work. Let’s elevate your projects with these invaluable tools!

Self Drilling Screw Custom Solutions, Your End-to-End Solution

Self-drilling screws are essential components in various industries, offering versatility and efficient installation for construction, automotive, and manufacturing applications. At the forefront of innovation, we provide tailored solutions that cater to the unique needs of global buyers, ensuring that you receive the highest quality products crafted to meet specific project requirements. Our end-to-end service encompasses everything from design and material selection to manufacturing and delivery. We understand that every project is distinct, which is why we work closely with our partners to develop custom solutions that align perfectly with their operational demands. Our extensive experience and commitment to quality guarantee that you will receive durable, reliable, and efficient self-drilling screws that enhance the performance and longevity of your products. Choosing our custom self-drilling screw solutions means you are investing in quality, efficiency, and service excellence. Collaborate with us to achieve optimal results for your projects, ensuring you stay ahead in a competitive market while simplifying your procurement process. Let's redefine your fastening solutions together, one screw at a time.

Self Drilling Screw Custom Solutions, Your End-to-End Solution

| Application | Material | Coating | Drive Type | Diameter (mm) | Length (mm) |

|---|---|---|---|---|---|

| Metal Roofing | Stainless Steel | Zinc Plated | Hex | 4.8 | 50 |

| Woodworking | Carbon Steel | Black Oxide | Pozidriv | 3.5 | 40 |

| Drywall | Galvanized Steel | Natural Finish | Phillips | 3.0 | 25 |

| Concrete | Alloy Steel | Corrosion Resistant | Square | 6.0 | 75 |

| Metal Framing | Brass | Tin Coated | Torx | 5.0 | 60 |

Related Products