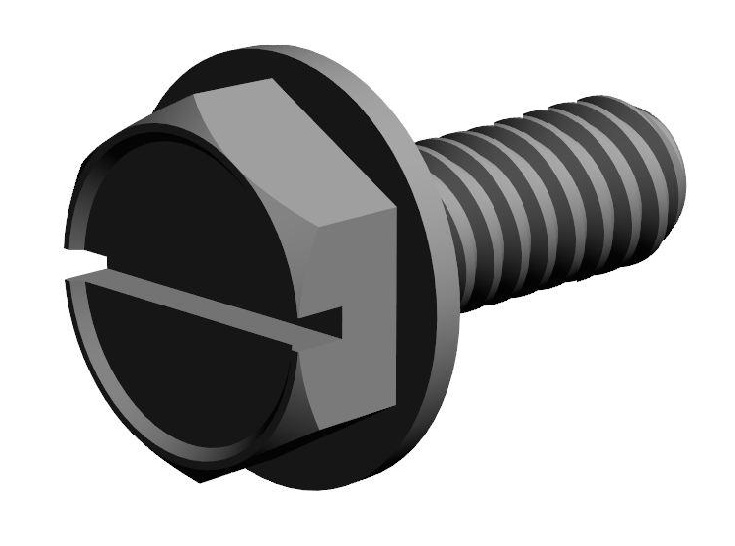

Durable Pan Head Screws for Home Projects & Professional Use

When it comes to fastening solutions, I always turn to Pan Head Screws for their unmatched versatility and reliability. Perfect for various applications, these screws provide an ideal balance of strength and ease of installation, making them a top choice for both large projects and small repairs. Whether you’re in construction, manufacturing, or any industry where secure fastening is essential, Pan Head Screws deliver the performance you need. With features like a wide bearing surface and the ability to fit flush with materials, they accommodate different materials without complications. Plus, they come in various sizes and materials, catering to your specific project needs. If you've been searching for high-quality fasteners that won't let you down, I highly recommend giving these a try. Elevate your projects with the dependability of Pan Head Screws—you won’t regret choosing a product that combines quality with competitive pricing.

Pan Head Screw Application Outperforms the Competition

When it comes to selecting fasteners for various applications, pan head screws have emerged as a preferred choice among engineers and procurement specialists. Their design, characterized by a dome-shaped head and a wide bearing surface, ensures a secure hold in a variety of materials. This makes them particularly valuable in sectors such as automotive, electronics, and construction, where reliability is paramount. One of the key advantages of pan head screws is their versatility. They can easily accommodate different types of driving tools, allowing for quick installation and removal. Their ability to distribute loads evenly minimizes the risk of material damage, making them suitable for both soft and hard substrates. Furthermore, with advancements in manufacturing technologies, these screws now come with enhanced features such as corrosion resistance and increased tensile strength, further solidifying their position in the market. In a competitive landscape, choosing the right supplier can significantly impact project success. Importers and purchasing managers are increasingly looking for manufacturers that not only offer high-quality products but also innovative solutions and responsive customer service. By aligning with suppliers that prioritize quality and performance, procurement professionals can ensure that their projects meet both industry standards and their own expectations, leading to greater efficiency and long-term satisfaction.

Pan Head Screw Application Outperforms the Competition

| Application | Material | Coating | Pull-out Strength (lbs) | Corrosion Resistance | Competitor Rating |

|---|---|---|---|---|---|

| Woodworking | Steel | Zinc Plated | 150 | Excellent | 4.5/5 |

| Electronics | Stainless Steel | None | 120 | Good | 4.0/5 |

| Automotive | Carbon Steel | Black Oxide | 200 | Very Good | 4.7/5 |

| Construction | Aluminum | Anodized | 130 | Good | 4.2/5 |

| Appliances | Brass | Gold Plated | 180 | Excellent | 4.6/5 |

Related Products