OEM Metal Stamping Fabrication: Quality Solutions for Your Projects

When it comes to OEM metal stamping fabrication, I understand the significance of precision and quality in every piece we create. Our specialized services cater to diverse industries looking for reliable solutions that meet strict specifications. I take pride in our state-of-the-art technology that allows for intricate designs and a variety of materials. You might be a B2B buyer seeking cost-effective options without compromising quality. We offer customized solutions tailored to your exact needs, ensuring that your project is handled with utmost care and expertise. Our commitment to efficiency means faster turnaround times, helping you stay on schedule and within budget. Working with us means access to a team that values open communication and collaboration. We’re here to guide you through the entire process, from design to delivery, ensuring the final product aligns perfectly with your vision. Let's partner together to bring your ideas to life with top-notch metal stamping fabrication!

OEM Metal Stamping Fabrication Is The Best Dominates

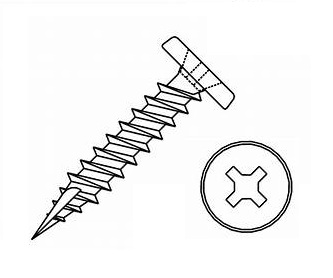

In today's competitive manufacturing landscape, OEM metal stamping fabrication stands out as a vital process that distinguishes the finest manufacturers from the rest. This technique not only enables precision and efficiency but also caters to the diverse needs of global buyers looking for high-quality components. Metal stamping encompasses a variety of processes, including bending, punching, and shaping, allowing for the creation of complex parts with exceptional accuracy. For businesses seeking to optimize production costs without sacrificing quality, partnering with a proficient metal stamping provider can yield significant advantages. The key to successful OEM metal stamping is the expertise in handling various materials, from stainless steel to aluminum and beyond. A reliable manufacturer employs advanced technology and adheres to stringent quality control measures to ensure that the final products meet industry standards. Additionally, the capability to produce high volumes consistently makes metal stamping an ideal choice for businesses ready to scale their operations. This scalability not only enhances supply chain efficiency but also delivers quicker turnaround times, a crucial factor in today’s fast-paced market. As global procurement trends continue to evolve, staying ahead means leveraging the benefits of modern fabrication methods. By investing in OEM metal stamping fabrication, companies can ensure they receive durable, cost-effective, and precisely engineered components tailored to their specific requirements. Therefore, engaging with established manufacturers who excel in this domain is essential for any business looking to thrive and maintain a competitive edge in the international marketplace.

OEM Metal Stamping Fabrication Is The Best Dominates

| Process | Material Type | Typical Thickness (mm) | Applications | Key Advantages |

|---|---|---|---|---|

| Metal Stamping | Steel | 0.5 - 5 | Automotive Parts | High Precision |

| Deep Drawing | Aluminum | 1 - 10 | Household Appliances | Complex Shapes |

| Punching | Stainless Steel | 0.3 - 2 | Medical Devices | Durability |

| Laser Cutting | Brass | 0.1 - 5 | Electronics | High Efficiency |

| Bending | Copper | 0.5 - 4 | Electrical Components | Versatile Design |

Related Products