Long Spring Nut: Essential Guide for Quality and Performance Needs

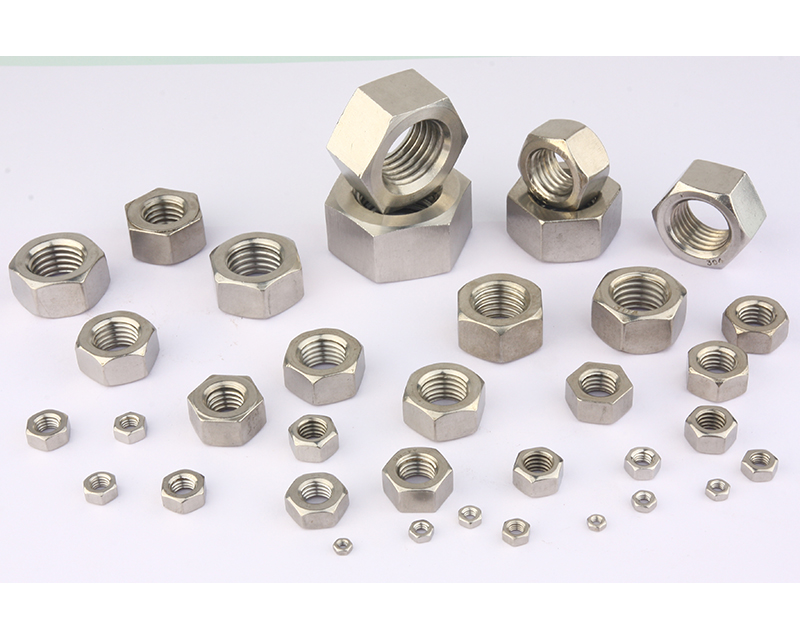

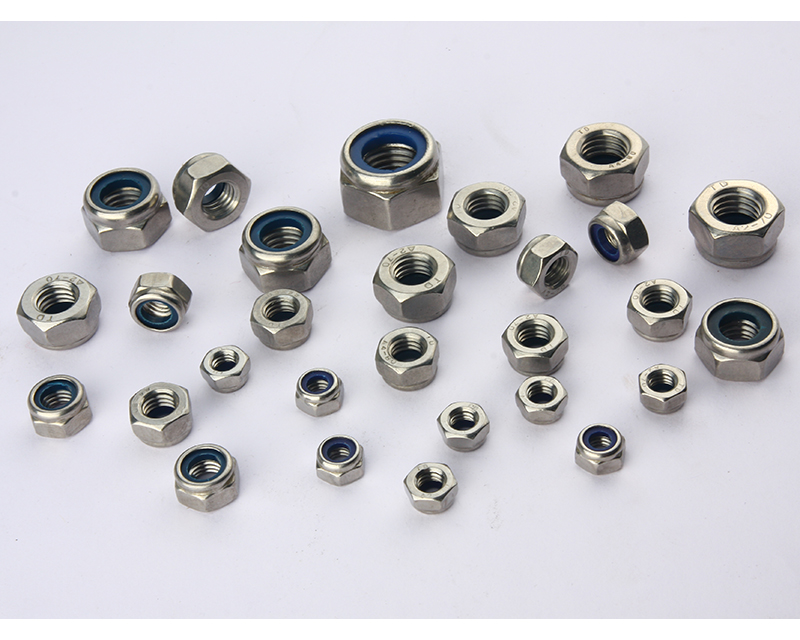

Are you in need of durable and reliable hardware solutions? The Long Spring Nut stands out as an essential component for various applications, ensuring a secure fit and enhanced performance. I’ve seen how it can elevate machinery reliability and streamline assembly processes. With its unique design and strong material, this nut provides exceptional resistance to wear and tear, making it perfect for demanding industrial environments. When purchasing, consider the ease of use and compatibility with existing fasteners; the Long Spring Nut fits effortlessly into your systems. I've found that this product not only saves time during installation but also reduces maintenance costs. Whether you're involved in manufacturing, construction, or automotive sectors, prioritizing quality with the Long Spring Nut is a smart choice that pays off in the long run. Don’t miss out—transform your operations with a reliable fastening solution today!

Long Spring Nut Is The Best Winning in 2025

As we look toward 2025, the manufacturing landscape continues to evolve, and one product stands out as a game-changer: the Long Spring Nut. This innovative fastening solution is poised to address the unique needs of global buyers by combining durability, versatility, and cost-effectiveness. With a design that enhances load distribution and reduces the risk of loosening under vibrational stress, the Long Spring Nut is ideal for a variety of applications, from automotive to construction. What sets the Long Spring Nut apart is its advanced materials and precision engineering. Many industries require fasteners that can withstand extreme conditions, and the Long Spring Nut meets this challenge with its superior resilience and corrosion resistance. This means less maintenance and longer service life, providing excellent value for procurement professionals aiming to optimize their supply chains. As more companies prioritize sustainable practices, the Long Spring Nut's longevity contributes to waste reduction and supports eco-friendly initiatives. As global procurement trends shift towards sustainable and high-performance solutions, embracing the Long Spring Nut could be a strategic move. Its compatibility with numerous manufacturing processes and ability to meet international quality standards make it an essential component for businesses looking to maintain a competitive edge in the years to come. Investing in this innovative fastening technology not only enhances product quality but also positions buyers for success in a dynamic market environment.

Long Spring Nut Is The Best Winning in 2025

| Category | Dimension (mm) | Material | Weight (g) | Coating | Application |

|---|---|---|---|---|---|

| Type A | 10 x 20 | Steel | 15 | Zinc | Automotive |

| Type B | 15 x 25 | Stainless Steel | 20 | Chrome | Aerospace |

| Type C | 20 x 30 | Aluminum | 10 | Anodized | Electronics |

Related Products