Lock Washer for Cheese Head Screw: Enhance Fastening Stability Today

When it comes to securing your machinery, I've found that the right lock washer for a cheese head screw can make all the difference. Our lock washers provide superior grip and reliability, ensuring your screws remain tight and secure under various conditions. Whether you're in manufacturing or assembly, using the correct fastener is crucial for optimal performance. I've noticed that many buyers appreciate the durability and design of our lock washers, which are engineered for long-lasting use. They’re perfect for high-torque applications and help prevent loosening due to vibration. Plus, with easy installation, it saves time on the assembly line. I believe that investing in quality components is essential for any project, especially in competitive markets. With our lock washers, you’ll find the perfect blend of quality and efficiency that elevates your products and meets your B2B needs.

Lock Washer For Cheese Head Screw Application Service

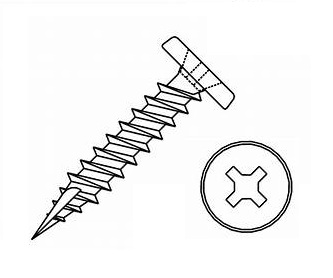

When it comes to securing components in machinery and various applications, the choice of fasteners can greatly impact performance and reliability. One essential component that often goes overlooked is the lock washer, particularly for cheese head screws. Lock washers are designed to prevent screw loosening due to vibration or torque, making them crucial in applications where safety and durability are paramount. The unique design of lock washers allows them to create tension in the connection, maintaining a stable hold even under challenging conditions. For cheese head screws, which feature a cylindrical head and a recessed drive, using the right lock washer can enhance efficiency and prevent damage to both the screw and the material being fastened. This combination is particularly valuable in industries such as automotive, aerospace, and construction, where failure isn't an option. Choosing the appropriate lock washer involves understanding the specific requirements of your application, including factors like load, environment, and material compatibility. By ensuring high-quality materials and precise manufacturing processes, you can trust that your connections will remain secure, enhance the longevity of your products, and ultimately contribute to smoother operations in any project. Investing in the right components can make all the difference in your overall success.

Lock Washer For Cheese Head Screw Application Service

| Material | Diameter (mm) | Thickness (mm) | Finish | Application |

|---|---|---|---|---|

| Stainless Steel | 10 | 1.2 | Passivated | General Use |

| Carbon Steel | 12 | 1.5 | Zinc Plated | Automotive |

| Aluminum | 8 | 1.0 | Anodized | Aerospace |

| Brass | 15 | 1.2 | Natural | Electrical |

| Plastic | 5 | 0.8 | Colored | Household |

Related Products