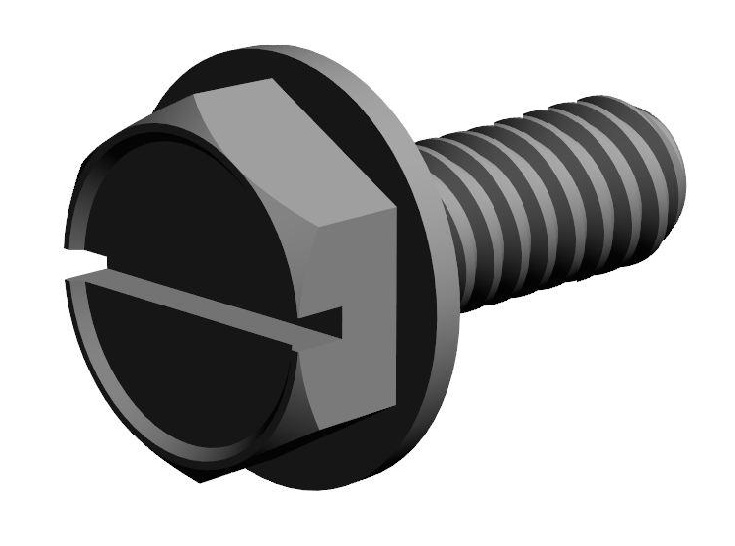

Hexagon Socket Countersunk Head Screws for Reliable Fastening Solutions

When I need reliable fasteners, I reach for hexagon socket countersunk head screws. These screws provide a sleek, flush finish that's perfect for applications where aesthetics matter. Their unique countersunk design allows them to sit neatly against the surface, minimizing protrusion and enhancing overall appearance. I appreciate the strong grip of the hex socket head, which ensures secure fastening even in challenging materials. Plus, with their high corrosion resistance and durability, I know they can withstand the test of time, making them ideal for both indoor and outdoor use. If your business values quality and performance in fasteners, consider adding these hexagon socket countersunk head screws to your procurement list. They not only simplify assembly but also improve the finished look of your projects. When precision and style matter, these screws are a must-have in my toolkit. Let's elevate your manufacturing standards together!

Hexagon socket coutersunk head screw Supplies the World\u2019s Top Brands Where Service Meets Innovation

In an ever-evolving manufacturing landscape, the demand for high-quality fasteners like hexagon socket countersunk head screws continues to rise globally. These screws are crucial in providing strength and stability in various applications, from automotive to electronics. The seamless integration of innovative design and exceptional service has become a pivotal aspect for suppliers aiming to meet the expectations of leading brands worldwide. By continuously enhancing product quality and exploring new technologies, manufacturers are positioned to support the most stringent industry standards. What sets apart top suppliers in this sector is their commitment to innovation paired with customer service excellence. Leveraging advanced manufacturing techniques and stringent quality control processes, they ensure that every hexagon socket screw not only meets but exceeds user expectations. Furthermore, these suppliers place a keen focus on understanding the unique needs of their clientele, enabling them to provide tailored solutions that enhance operational productivity and efficiency. In a global market where competition is fierce, connecting with suppliers who prioritize innovation and customer-centric service can streamline procurement processes and foster long-term partnerships. As brands seek reliable sources for their fastener needs, the emphasis on quality and service will play a crucial role in maintaining a competitive edge and achieving operational success.

Hexagon Socket Countersunk Head Screw Supplies the World’s Top Brands Where Service Meets Innovation

| Material | Diameter (mm) | Length (mm) | Finish | Head Style | Application |

|---|---|---|---|---|---|

| Steel | 6 | 20 | Zinc Plated | Countersunk | Electrical Devices |

| Stainless Steel | 8 | 25 | Passivated | Countersunk | Construction |

| Carbon Steel | 10 | 30 | Black Oxide | Countersunk | Machinery |

| Brass | 5 | 15 | Natural | Countersunk | Furniture |

| Aluminum | 12 | 40 | Anodized | Countersunk | Automotive |

Related Products