Hex Wood Screw: Essential Fasteners for DIY and Home Improvement Projects

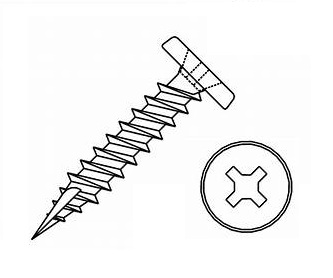

When I’m in need of reliable fastening solutions, the Hex Wood Screw is always my go-to choice. These screws offer exceptional grip and stability for all woodworking projects, ensuring everything stays in place, no matter the demand. Their hex head design makes installation a breeze, allowing for quick and easy driving, especially in tight spots. I appreciate how these screws are engineered for durability, resisting stripping and corrosion, which is crucial for long-lasting applications. Whether I’m working on furniture assembly or constructing wood structures, I know I can count on the strength that hex wood screws provide. While browsing for fasteners, I prioritize quality and performance—the hex wood screws consistently meet my expectations. They’re available in various sizes and finishes, making them perfect for any project. If you're serious about craftsmanship, choosing the right screw can make all the difference. Let’s elevate our woodworking experience together!

Hex Wood Screw Is The Best Dominates

When it comes to choosing the right fasteners for woodworking applications, hex wood screws stand out as the superior choice. Their unique design allows for enhanced torque transfer, making them ideal for securing materials with precision and strength. Unlike traditional screws, hex wood screws offer superior grip in softer woods, preventing stripping and providing a more reliable hold. This makes them an invaluable asset for both professional carpenters and DIY enthusiasts alike. Moreover, the versatility of hex wood screws means they can be used in a variety of applications, from furniture assembly to large construction projects. Their corrosion-resistant coatings ensure durability, even in outdoor environments, which is a significant consideration for global sourcing. As industries continue to prioritize efficiency and sustainability, choosing high-quality, reliable products like hex wood screws can lead to long-term cost savings and enhanced project outcomes. Incorporating hex wood screws into your procurement strategy not only elevates the quality of your products but also aligns with the growing demand for dependable and innovative solutions in the global market. By making the switch, you can ensure that your projects are built to last, positioning yourself as a leader in quality and craftsmanship.

Hex Wood Screw Is The Best Dominates

| Screw Type | Material | Size (mm) | Driver Type | Coating | Usage |

|---|---|---|---|---|---|

| Hex Head Screw | Steel | 50 | Hex | Zinc Plated | Wood Assembly |

| Lag Screw | Stainless Steel | 60 | Square | Black Oxide | Heavy Duty Applications |

| Deck Screw | Coated Steel | 75 | Torx | Corrosion Resistant | Outdoor Decking |

| Wood Screw | Brass | 40 | Phillips | Uncoated | Furniture Assembly |

| Self-Tapping Screw | Carbon Steel | 30 | Slotted | Phosphate | Metal to Wood |

Related Products