Hex Head Bolts: Durable Fasteners for Your Construction Needs

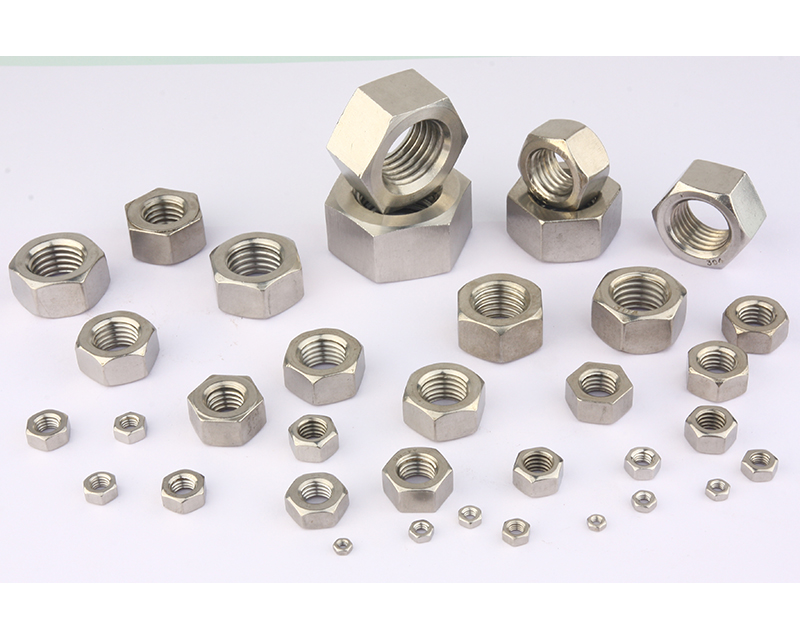

When I think about reliable fastening solutions, Hex Head Bolts always come to mind. These bolts provide unparalleled strength and durability, making them perfect for a variety of industrial applications. Whether you need to secure heavy machinery or construct robust frameworks, these bolts get the job done. I'm particularly impressed with their ease of installation; the hexagonal head allows for better torque transmission, which makes tightening a breeze. I often recommend Hex Head Bolts to my clients seeking high-quality products at competitive prices. They’re ideal for both heavy-duty and general purposes. Plus, they come in various grades and materials to match specific project needs. As a B2B purchaser, I understand the importance of sourcing components that not only meet industry standards but also fit within budget constraints. These bolts are a solid investment that ensures your projects remain stable and secure, no matter the conditions.

Hex Head Bolts Application Now Trending

Hex head bolts are gaining significant traction in various industries, reflecting their versatility and reliability in applications ranging from construction to machinery manufacturing. These bolts, characterized by their hexagonal heads that allow for easy fastening with wrenches, provide exceptional torque and load-bearing capabilities. Their design minimizes the risk of stripping, ensuring a secure fit, making them an ideal choice for critical assemblies where safety and durability are paramount. As global demand for high-quality fastening solutions continues to rise, hex head bolts are increasingly being used in innovative applications. Industries such as automotive and aerospace are integrating these fasteners into their production lines, favoring them for their strength and resistance to vibrations. Additionally, the growing shift towards sustainable manufacturing practices has reinforced the preference for hex head bolts made from eco-friendly materials, enabling companies to meet regulatory standards while optimizing performance. For procurement specialists and businesses, understanding the intricacies of hex head bolts can lead to better purchasing decisions. The trend highlights the importance of sourcing from reputable manufacturers who adhere to strict quality control processes. As the market evolves, keeping an eye on emerging technologies and material advancements within hex head bolt manufacturing will be key to maintaining a competitive edge in an ever-demanding global landscape.

Hex Head Bolts Application Now Trending

| Application Area | Material Type | Size (mm) | Coating Type | Strength Grade |

|---|---|---|---|---|

| Automotive | Steel | 10 | Zinc Plated | 8.8 |

| Construction | Stainless Steel | 12 | Coated | A2-70 |

| Marine | Bronze | 14 | None | C65100 |

| Aerospace | Titanium | 8 | Anodized | Grade 5 |

| Electronics | Aluminum | 6 | Anodized | 6061-T6 |

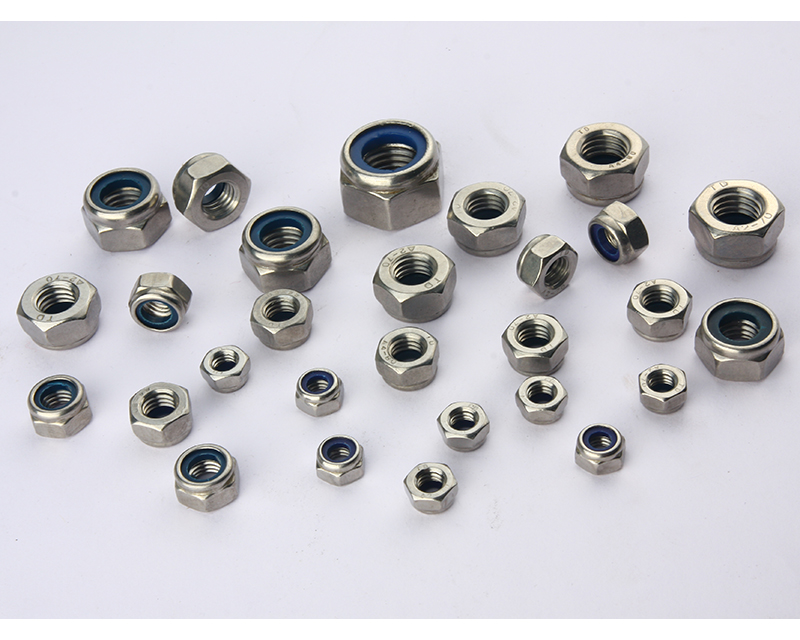

Related Products