Hex Flange Head Bolts for Enhanced Strength and Reliable Performance

When I search for reliable fastening solutions, Hex Flange Head Bolts always come to mind. These bolts offer superior grip and stability, making them perfect for various industrial applications. I love how their integrated flange distributes load, reducing the risk of loosening over time. Whether you're in construction or manufacturing, you’ll find these bolts invaluable. I appreciate the diverse options available, from different sizes to materials suitable for any environment. Knowing I can choose corrosion-resistant features gives me peace of mind for outdoor projects—talk about durability! Plus, with fast delivery options, I can keep my projects on schedule without the hassle. If you’re seeking quality and dependability, look no further than these hex flange head bolts. They really do make a difference in ensuring my work stands the test of time.

Hex Flange Head Bolts Service Custom Solutions,

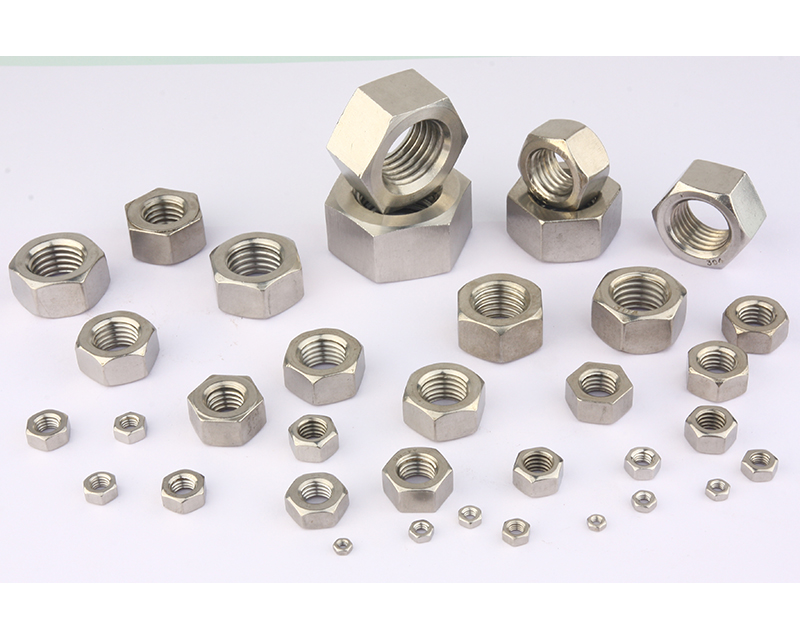

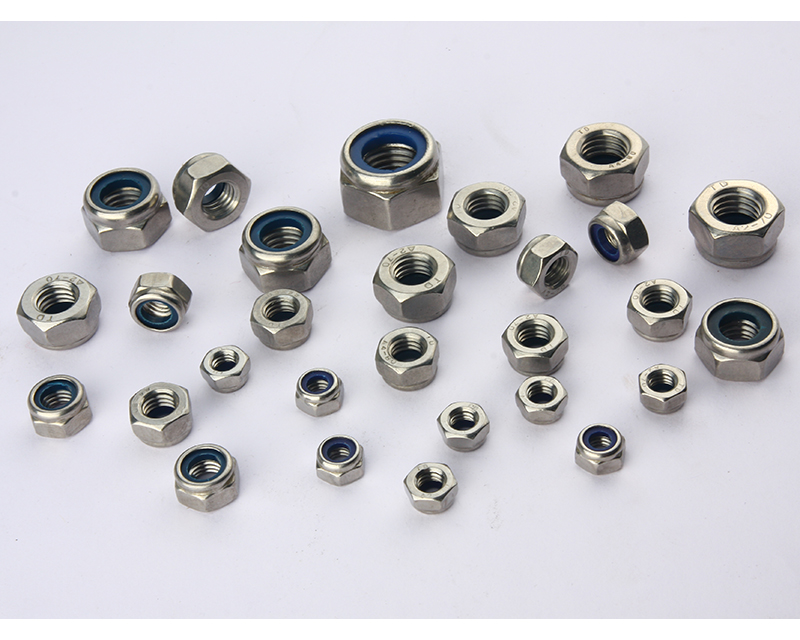

Hex flange head bolts are essential components in various industries, providing secure and reliable fastening solutions for a range of applications. Their unique design, featuring a circular flange beneath the head, enhances load distribution and stability, making them an ideal choice for heavy machinery, construction projects, and automotive manufacturing. As global suppliers strive to meet the diverse needs of their clients, custom solutions for hex flange head bolts have become increasingly important. Understanding that different applications demand specific features, manufacturers are now offering tailored options, including variations in material, size, and coating. Whether it's corrosion resistance for outdoor applications or specific thread patterns for enhanced grip, customized hex flange head bolts can significantly improve the performance and longevity of your products. Companies can benefit from collaborating with experienced suppliers who can provide expert insights and innovative solutions that align with their unique requirements. By investing in high-quality, custom hex flange head bolts, businesses can not only enhance the reliability of their assemblies but also optimize their production processes. As industries worldwide continue to evolve and place greater emphasis on quality and efficiency, leveraging specialized fastening solutions can provide a competitive edge in the global marketplace. With the right partners, companies can ensure that their projects are equipped with the best components to drive success.

Hex Flange Head Bolts Service Custom Solutions

| Material | Diameter (mm) | Length (mm) | Grade | Coating Type |

|---|---|---|---|---|

| Carbon Steel | 10 | 50 | 8.8 | Zinc Plated |

| Stainless Steel | 12 | 60 | A2-70 | None |

| Alloy Steel | 16 | 75 | 10.9 | Black Oxide |

| Brass | 8 | 40 | C36000 | Natural Finish |

Related Products