Top Flat Torx Socket Bolt Choices for Every DIY Project and Repair

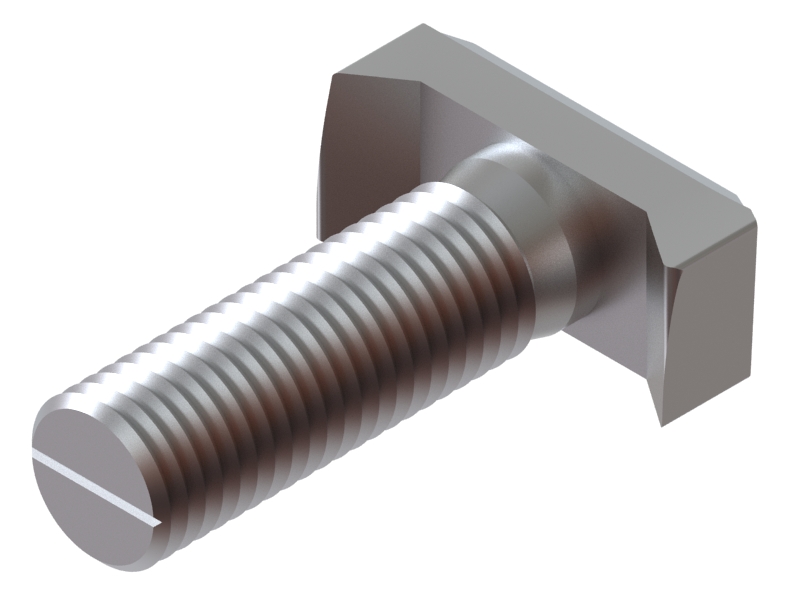

When I use the Flat Torx Socket Bolt, I feel confident in the strength and durability it brings to my projects. This product is perfect for those who value precision and reliability in their fasteners. It features a unique design that enhances grip and prevents stripping, making assembly and disassembly a breeze, whether in manufacturing or construction. I often recommend combining these bolts with a compatible socket wrench for optimal torque application. I've had great experiences using them in various applications, knowing they’ll hold up under stress. These bolts are essential for anyone who wants quality and efficiency at an economical price. If you're in the market for a dependable fastening solution that stands up to tough conditions, I highly suggest you add the Flat Torx Socket Bolt to your arsenal. It's a choice I won't regret, and one that can elevate the standards of your assembly work.

Flat Torx Socket Bolt in 2025 Custom Solutions,

In 2025, the demand for customized solutions in hardware manufacturing continues to rise, particularly for components like flat Torx socket bolts. These specialized fasteners offer superior torque transfer and enhanced grip, making them essential for various industrial applications. As global industries evolve, the need for innovative solutions tailored to specific operational requirements becomes paramount. Partnering with a reliable manufacturer that understands the nuances of custom solutions can significantly impact operational efficiency. Companies are now seeking flexibility in design and production processes to accommodate unique specifications, ensuring that components meet stringent quality standards. Investing in flat Torx socket bolts designed to precise dimensions and materials can lead to improved performance and durability, ultimately driving cost savings and increasing product lifespan. As we look toward the future, the emphasis on sustainability and eco-friendliness is also shaping purchasing decisions. Ensuring that manufacturing processes align with environmental considerations not only appeals to conscious buyers but also enhances brand reputation. Therefore, engaging with suppliers committed to innovation and sustainability will be crucial for procurement professionals aiming to stay ahead in an increasingly competitive market.

Flat Torx Socket Bolt in 2025 Custom Solutions

| Material | Finish | Head Size | Drive Size | Length | Torque Spec |

|---|---|---|---|---|---|

| Steel | Zinc Plated | T20 | 1/4" | 30 mm | 15 Nm |

| Aluminum | Anodized | T25 | 3/8" | 40 mm | 20 Nm |

| Stainless Steel | Passivated | T30 | 1/2" | 50 mm | 25 Nm |

Related Products