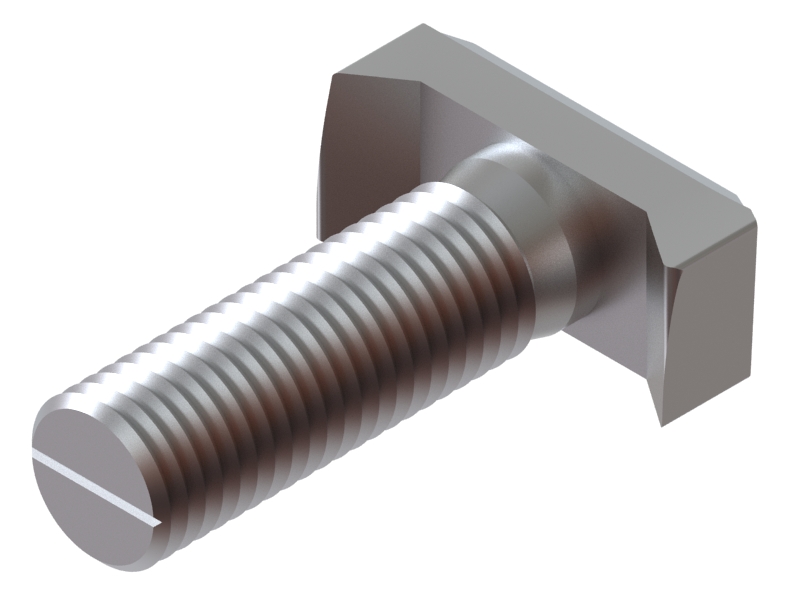

Discover Fanged Elevator Bolts: Quality & Durability for Your Projects

When I came across the Fanged Elevator Bolt, I knew it was exactly what I needed for my projects. These bolts are designed with precision, ensuring a secure grip in various applications. If you've ever dealt with unreliable hardware, you’ll appreciate the strength and reliability these bolts offer. Customers often look for durability and efficiency, and let me tell you, this bolt checks all the boxes. It can effectively withstand heavy loads and is ideal for elevator installations and other heavy machinery. Not only do these fanged bolts enhance performance, but they also simplify the installation process—saving time and reducing labor costs. When sourcing materials, I’ve found that a combination of reliability and cost-effectiveness is essential, and this product delivers on both. Whether you’re in maintenance, construction, or manufacturing, these Fanged Elevator Bolts can be a valuable addition to your inventory. You won’t be disappointed!

Fanged Elevator Bolt For the Current Year Ahead of the Curve

In the ever-evolving landscape of industrial hardware, the fanged elevator bolt stands out as an essential component for enhancing efficiency and reliability in various applications. As we move into the current year, the demand for high-quality fastening solutions continues to rise. Fanged elevator bolts are particularly valuable due to their unique design, which provides superior grip and stability, making them ideal for securing wooden and metal constructions in heavy-duty environments. Global procurement professionals should take note of the advanced manufacturing techniques and materials that enhance the durability and performance of these bolts. By utilizing high-grade steel and finishing processes, vendors can offer products that withstand wear and corrosion, ensuring long-lasting service even in the most challenging conditions. The rising trend towards sustainability also encourages the use of eco-friendly materials and practices in production, catering to the growing market preference for environmentally responsible choices. Investing in fanged elevator bolts offers businesses an edge in both operational efficiency and cost-effectiveness. As industries seek to optimize their supply chains, partnering with reliable suppliers who prioritize quality and innovation will be key. By aligning with manufacturers who understand the nuances of global procurement, companies can ensure they remain ahead of the curve, securing not just products, but also valuable partnerships in the competitive hardware market.

Fanged Elevator Bolt For the Current Year Ahead of the Curve

| Dimension (inches) | Material | Coating | Load Capacity (lbs) | Standard Compliance |

|---|---|---|---|---|

| 1.75 x 2.00 | Steel | Zinc Plated | 2000 | ASTM A307 |

| 2.00 x 2.50 | Stainless Steel | Passivated | 2500 | ASTM F593 |

| 1.50 x 1.75 | Carbon Steel | Hot-Dip Galvanized | 1800 | AASHTO M-314 |

| 2.25 x 3.00 | Alloy Steel | Black Oxide | 3000 | ISO 898-1 |

Related Products