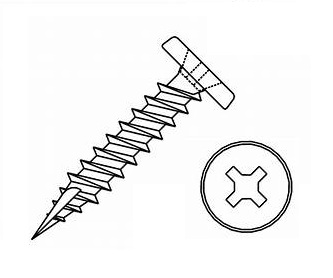

Custom Philips Head Screw: Tailored Solutions for Your Project Needs

When I think about quality and precision in fasteners, the custom Philips head screw stands out. Designed for versatility, these screws are perfect for a variety of applications, ensuring a secure fit every time. It’s all about the details; I can tailor the head size and thread type to fit your specific needs, providing a perfect match for your projects. I understand that durability matters. That’s why my custom Philips head screws are crafted from high-grade materials, ensuring they withstand even the toughest environments. Whether you're in manufacturing or construction, having reliable fasteners at hand is crucial for your bottom line. And if you’re worried about volume? Don't be. I can accommodate bulk orders, making the purchasing process efficient and cost-effective. Let's streamline your sourcing with a product that meets your high standards while staying within budget. Reach out, and let’s discuss what custom solutions we can create together!

Custom Philips Head Screw Winning in 2025 Your End-to-End Solution

As the global landscape for manufacturing and procurement evolves, the demand for tailored solutions continues to rise. The custom Philips head screw is not just a component; it is a cornerstone of efficiency and reliability in various industries, from automotive to electronics. In 2025 and beyond, companies will need a comprehensive end-to-end solution that addresses specific needs while ensuring quality and consistency. Our approach to manufacturing custom Philips head screws emphasizes flexibility and precision. By utilizing advanced technology and adhering to international standards, we can produce screws that meet the unique specifications required by our clients. Moreover, our streamlined supply chain ensures that from design to delivery, every step is optimized for performance and speed. The growing trend towards personalized products presents an opportunity for global buyers to enhance their offerings. A partnership with a manufacturer that prioritizes innovation and customer satisfaction can significantly impact your success. By choosing a provider that understands the intricacies of your industry, you position your products for excellence in the competitive market of 2025. Embrace the future with customized solutions that pave the way for operational triumph and product integrity.

Custom Philips Head Screw Winning in 2025 Your End-to-End Solution

| Feature | Description | Applications | Material | Sizes Available |

|---|---|---|---|---|

| Custom Design | Tailored screw design to meet specific needs. | Electronics, automotive, home appliances | Stainless Steel | M3, M4, M5, M6 |

| High Corrosion Resistance | Suitable for outdoor and humid environments. | Construction, HVAC | Coated Steel | M2, M3, M4 |

| Increased Torque | Designed for better grip and torque application. | Industrial Machinery, Robotics | Titanium Alloy | M4, M5, M6, M8 |

| Environmentally Friendly | Made from recyclable materials. | Consumer Goods, Furniture | Recycled Steel | M3, M4, M5 |

Related Products