Top Countersunk Head Bolt Options for Your Project Needs

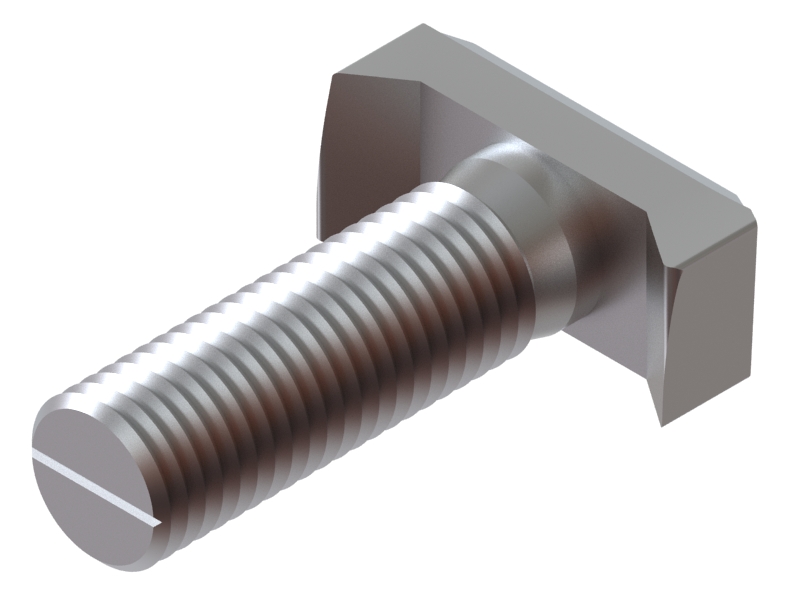

When I work on projects, having the right fasteners is crucial, and that's why I always choose countersunk head bolts. These bolts not only provide a sleek finish but also sit flush with the surface, making them ideal for applications where an aesthetic look is important. I appreciate how they prevent snagging and potential injuries in tight spaces, which is especially relevant in heavy machinery or construction settings. With a variety of sizes and materials available, I can easily find the right countersunk head bolt for my specific needs. Their exceptional strength and durability mean they stand up well over time, even in demanding environments. Plus, they’re compatible with many types of nuts and washers, giving me flexibility in my projects. Whether I'm securing panels or installing equipment, these bolts provide the reliability I need to ensure everything holds together perfectly. Trust me, once you try them, you’ll understand why they’re a staple in my toolkit!

Countersunk Head Bolt Application Supplies the World\u2019s Top Brands

In the realm of hardware solutions, countersunk head bolts have emerged as essential components for various applications across industries. These fasteners, designed to sit flush with the surface of the material they are affixed to, provide not only a sleek aesthetic but also enhanced safety by minimizing snag points. Their versatility makes them ideal for use in furniture production, automotive manufacturing, and construction, particularly in settings where space is at a premium and visual appeal is paramount. The demand for high-quality countersunk head bolts is surging, as global brands prioritize reliability and performance. Manufacturers are now focusing on innovative production techniques and quality materials to ensure that these fasteners meet rigorous industry standards. By partnering with suppliers offering a diverse range of products tailored to specific needs, businesses can secure the competitive edge they seek in their respective markets. As industries evolve and technological advancements continue to shape manufacturing processes, investing in reliable hardware components becomes critically important. Adopting premium-grade countersunk head bolts not only enhances product durability but also fosters trust with end-users. With a commitment to quality and performance, businesses can effectively navigate the evolving landscape of global supply chains, providing their customers with the best in fastener technology.

Countersunk Head Bolt Application Supplies the World’s Top Brands

| Application | Industry | Material | Finish | Size |

|---|---|---|---|---|

| Automotive Assembly | Automotive | Steel | Zinc Plated | M6 x 50mm |

| Electronics Enclosure | Electronics | Aluminum | Anodized | M4 x 20mm |

| Furniture Assembly | Furniture | Brass | Polished | M5 x 30mm |

| Machinery Assembly | Manufacturing | Stainless Steel | Black Oxide | M8 x 40mm |

| Construction | Construction | High-Strength Steel | Galvanized | M10 x 60mm |

Related Products