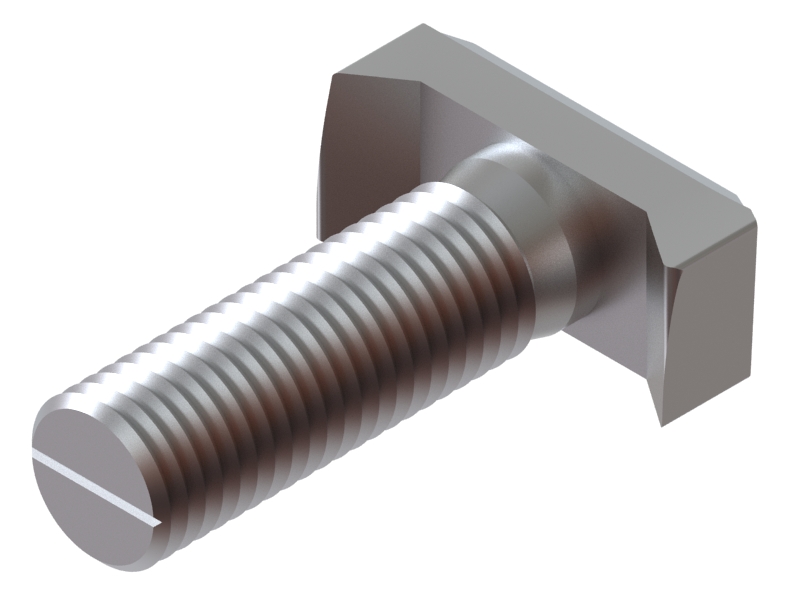

Truss Head Square Neck Carriage Step Bolts for Durable Fastening Solutions

When efficiency and strength matter in your projects, Truss Head Square Neck Carriage Step Bolts are the perfect choice. I often turn to these bolts because they provide a reliable fastening solution, especially in construction and heavy-duty applications. With their unique truss head design, they distribute pressure evenly, preventing damage to the surfaces they're attached to. Plus, the square neck ensures a secure grip into the material, reducing the chances of loosening over time. I've found that these bolts are not just strong, but they're also easy to install, making my work smoother and more efficient. The high-quality material guarantees durability, standing up to the rigors of any job. Whether you're building a deck or securing heavy machinery, these bolts meet the demands. If you're in the market for dependable fasteners, consider the Truss Head Square Neck Carriage Step Bolts – you won’t regret it!

Truss Head Square Neck Carriage Step Bolts Industry Leaders Where Innovation Meets 2025

In the ever-evolving landscape of industrial hardware, the truss head square neck carriage step bolts stand out as a prime example of innovation and functionality. As global markets continue to demand products that combine durability with design, these fasteners have captured the attention of procurement professionals seeking reliable solutions for their projects. Engineered to deliver optimal performance, these carriage bolts are not only easy to install but also provide superior locking capabilities, ensuring stability and strength in various applications. As we look toward 2025, the emphasis on sustainable and efficient manufacturing practices has never been more critical. Leading manufacturers in the industry are making strides to incorporate eco-friendly materials and processes in the production of fasteners, minimizing environmental impact while maintaining high-quality standards. This shift not only meets the rising demand for responsible sourcing among global buyers but also enhances the overall value and longevity of industrial hardware solutions. With a firm commitment to innovation, manufacturers continue to invest in advanced technologies and research to stay ahead in a competitive market. As procurement leaders consider their options, the upcoming trends in truss head square neck carriage step bolts promise not only functionality but also aesthetic versatility, making them an ideal choice for a wide range of applications—from construction and automotive to furniture assembly. Embracing these advancements will undoubtedly set the stage for successful partnerships and sustainable growth in the hardware industry.

Truss Head Square Neck Carriage Step Bolts Industry Leaders Where Innovation Meets 2025

| Company | Country | Market Share (%) | R&D Investment (Million USD) | Sustainability Rating |

|---|---|---|---|---|

| Company A | USA | 25 | 15 | A |

| Company B | Germany | 20 | 10 | B |

| Company C | China | 15 | 5 | C |

| Company D | Japan | 18 | 7 | A- |

| Company E | UK | 22 | 12 | B+ |

Related Products