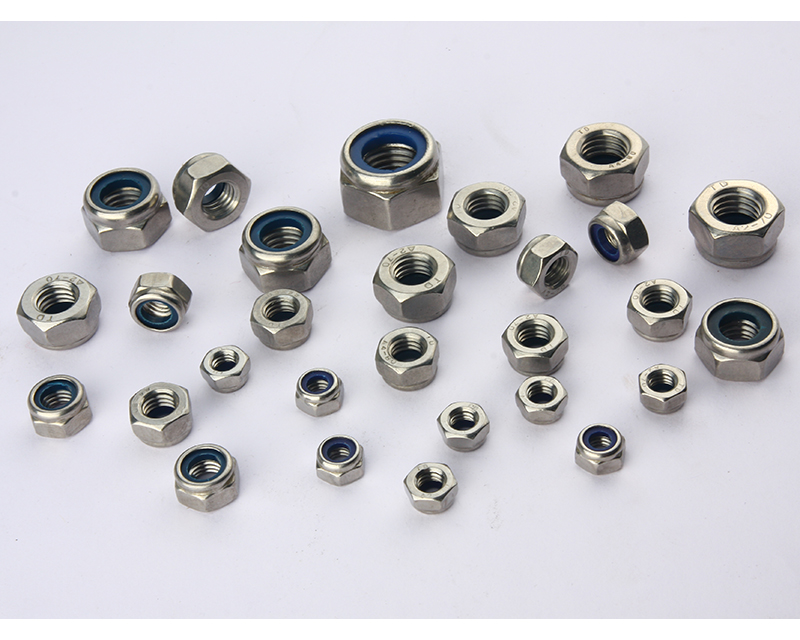

Explore Various Lock Nut Types for Your Next Project Needs

When it comes to selecting the right lock nut types for your projects, I know how crucial it is to find the perfect fit for your specific needs. Whether you're in construction, manufacturing, or automotive, the right lock nut can make all the difference in securing your components. I’ve seen firsthand how essential it is for buyers to consider durability and reliability when choosing fasteners. Our range of lock nut types offers options that cater to various applications, ensuring that you don’t have to compromise on quality. Plus, we provide detailed specifications and competitive pricing to make your purchasing process easier. With my experience in the industry, I'm here to help guide you towards the best choices for your projects. Let’s take your operations to the next level with lock nuts that give you peace of mind and performance.

Lock Nut Types Exceeds Industry Benchmarks Your Trusted OEM Partner

When it comes to the manufacturing of lock nuts, exceeding industry benchmarks is not just a goal but a commitment to quality and reliability. Various types of lock nuts are essential components in numerous applications, from automotive to aerospace, and choosing the right one can significantly impact the overall performance of a project. Understanding the different types available and their unique features can aid global purchasers in making informed decisions that align with their operational needs. Innovative designs such as nylon-insert lock nuts, prevailing torque lock nuts, and castle nuts are frequently utilized across industries to prevent loosening under vibration. Each type offers distinct advantages; for instance, nylon-insert lock nuts provide excellent resistance to vibrations and are ideal for lightweight applications, while prevailing torque lock nuts are perfect for heavy-duty uses where stability is crucial. By choosing an OEM partner who adheres to stringent quality standards, buyers can ensure that they receive products that not only meet but exceed expectations in performance, durability, and safety. Partnering with a reliable manufacturer streamlines the procurement process, allowing businesses to focus more on their core operations. With a vast range of lock nut types designed to meet specific industry demands, a trusted manufacturer can cater to the unique requirements of clients around the globe. By investing in high-quality components, organizations can enhance their product reliability, reduce maintenance costs, and ultimately secure a competitive edge in their respective markets.

Lock Nut Types Exceeds Industry Benchmarks

| Nut Type | Material | Size (mm) | Locking Mechanism | Applications |

|---|---|---|---|---|

| Nylon Insert Lock Nut | Steel | M8 | Nylon Insert | Automotive |

| Prevailing Torque Lock Nut | Carbon Steel | M10 | Deformed Threads | Machinery |

| Castle Nut | Stainless Steel | M12 | Pin Lock | Bicycle |

| Lock Washers | Flat Steel | M6 | Spring Action | Electrical |

| Hex Lock Nut | Nickel Plated Steel | M16 | Friction Lock | Construction |

Related Products