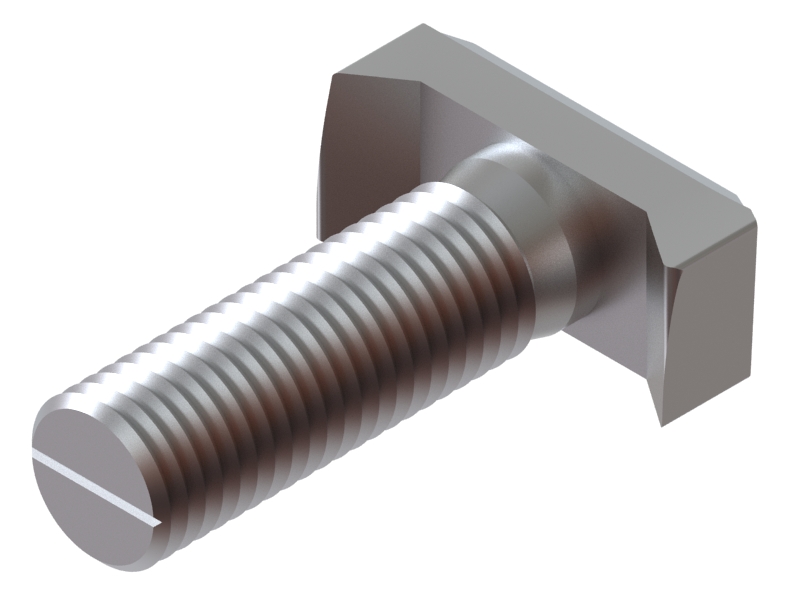

Head Square Neck Bolts: Best Options for Your Project Needs

When I first came across Head Square Neck Bolts, I knew they were exactly what I needed for my industrial projects. These bolts, designed to provide a secure fit and high torque, are perfect for heavy machinery and structural applications. I've always appreciated the unique square neck design, which prevents rotation when fastening. With their robust construction, these bolts stand up to demanding environments, ensuring reliability and longevity. I often find myself recommending them to colleagues looking for quality and durability at a competitive price. Whether you’re in construction, manufacturing, or maintenance, Head Square Neck Bolts are the go-to solution for better performance. Plus, their versatility makes them suitable for various applications. If you're leaning towards making a smart purchase, think about these bolts; they won’t disappoint you!

Head Square Neck Bolts in 2025 Industry Giant

As the global market for fasteners continues to evolve, the significance of head square neck bolts has never been more pronounced. These fasteners are not just essential components; they play a crucial role in ensuring structural integrity across various industries, including construction, automotive, and machinery. As manufacturers strive to enhance the reliability and performance of their products, the demand for innovative fastening solutions is growing rapidly. The year 2025 is poised to see significant advancements in materials and manufacturing processes that will elevate head square neck bolts to new heights. In recent years, industry giants have been investing in research and development to improve the properties of these fasteners, such as corrosion resistance, tensile strength, and overall durability. The shift towards lightweight yet robust materials is also reshaping the design and application of head square neck bolts, making them increasingly versatile for diverse applications. This trend not only meets the demands of safety and efficiency but also aligns with sustainability goals, as many manufacturers prioritize eco-friendly practices in their production. For global procurement professionals, understanding the latest trends and innovations in head square neck bolts is essential for making informed purchasing decisions. Staying updated on industry developments will enable businesses to source high-quality products that meet their operational needs while maintaining a competitive edge in an ever-changing market. As we look ahead to 2025, the promise of head square neck bolts as a staple in the fastener industry is clear, and the opportunities for collaboration and growth are abundant.

Head Square Neck Bolts in 2025 Industry Giant

| Material Type | Size (mm) | Strength (MPa) | Coating Type | Market Demand (%) |

|---|---|---|---|---|

| Carbon Steel | 10 | 350 | Zinc Plating | 30 |

| Stainless Steel | 12 | 550 | Passivation | 25 |

| Alloy Steel | 14 | 800 | Black Oxide | 20 |

| Brass | 16 | 300 | Natural | 15 |

| Titanium | 8 | 900 | Anodized | 10 |

Related Products