Galvanized Nut: Durable Solutions for Your Project Needs

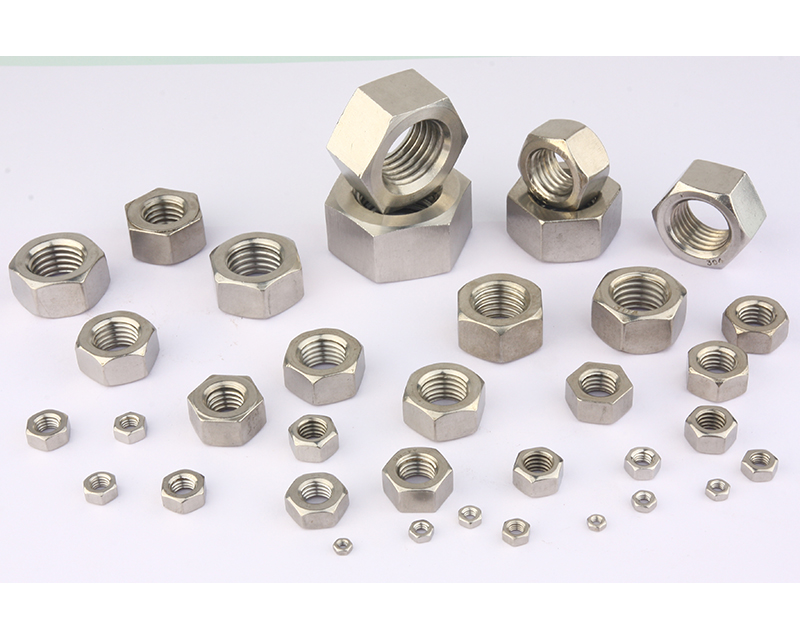

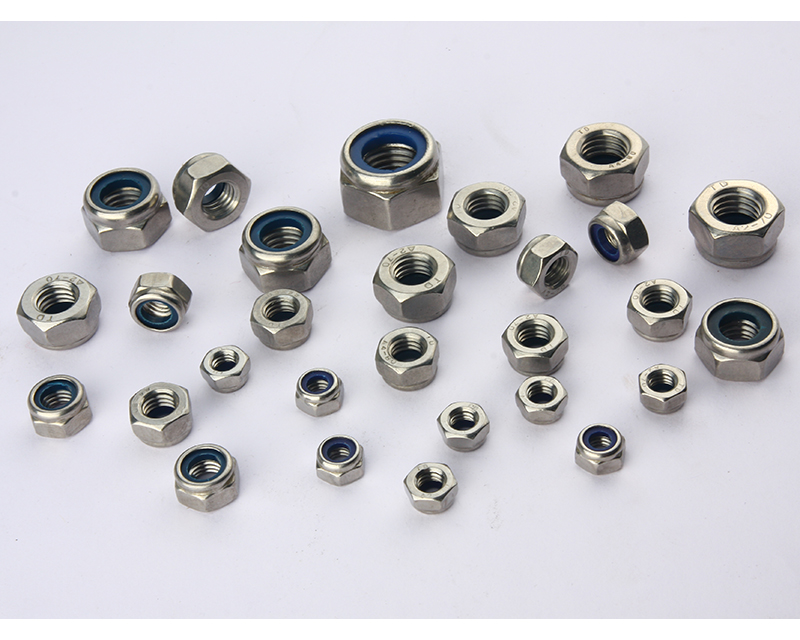

When I’m sourcing quality fasteners for our projects, the galvanized nut always stands out as a preferred option. Their rust-resistant coating not only enhances durability but also ensures they hold up in challenging environments. Whether you’re dealing with heavy machinery or outdoor installations, I find these nuts provide the reliability we need. What I love about galvanized nuts is their versatility. They’re perfect for a range of applications, from construction to manufacturing, making them a go-to choice for anyone looking to secure components tightly. Plus, they are available in various sizes, ensuring we can get exactly what we need for our specific requirements. It's also important for me to work with suppliers who understand our urgency and can provide timely delivery. Quality and efficiency matter, and I’ve found that my go-to suppliers for galvanized nuts always have my back. Investing in these fasteners is a decision I never regret, as they consistently deliver solid performance and longevity.

Galvanized Nut Now Trending Guarantees Peak Performance

In a competitive marketplace, the choice of hardware components can significantly influence the success of your projects. Galvanized nuts are now trending due to their exceptional durability and corrosion resistance, making them a preferred choice for various industries. These nuts are treated with a protective zinc coating that not only enhances their longevity but also ensures peak performance under challenging conditions, from construction sites to outdoor installations. As global procurement professionals seek reliable and robust components, the demand for galvanized nuts continues to rise. Their versatility allows them to be utilized in a broad spectrum of applications, whether in manufacturing, automotive assembly, or construction projects. By opting for galvanized nuts, businesses can ensure that their structures and machinery maintain integrity over time, ultimately leading to reduced maintenance costs and improved operational efficiency. Investing in high-quality galvanized nuts is not just a trend; it’s a strategic decision that can drive performance and reliability in every aspect of production. For procurement specialists, understanding the quality standards and manufacturing processes behind these essential components is crucial. Embracing this trend ensures you stay ahead in the market while providing your clients with the best possible solutions for their needs.

Galvanized Nut Now Trending Guarantees Peak Performance

| Dimension | Material | Coating Type | Tensile Strength (MPa) | Corrosion Resistance |

|---|---|---|---|---|

| M6 | Steel | Hot-dip Galvanized | 400 | Excellent |

| M8 | Steel | Electro Galvanized | 500 | Good |

| M10 | Steel | Hot-dip Galvanized | 600 | Very Good |

| M12 | Steel | Electro Galvanized | 700 | Good |

Related Products