Galvanized Carriage Bolt and Nut: Essential Fasteners for Your Projects

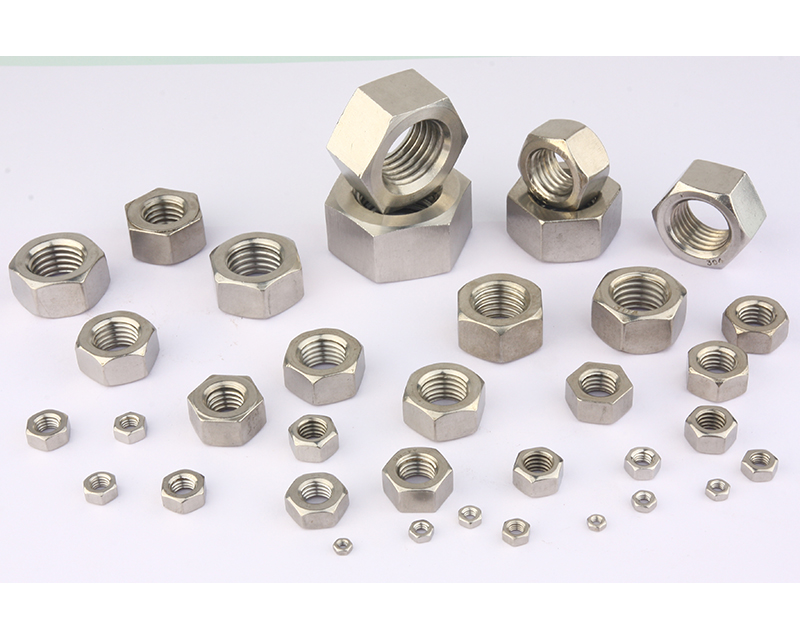

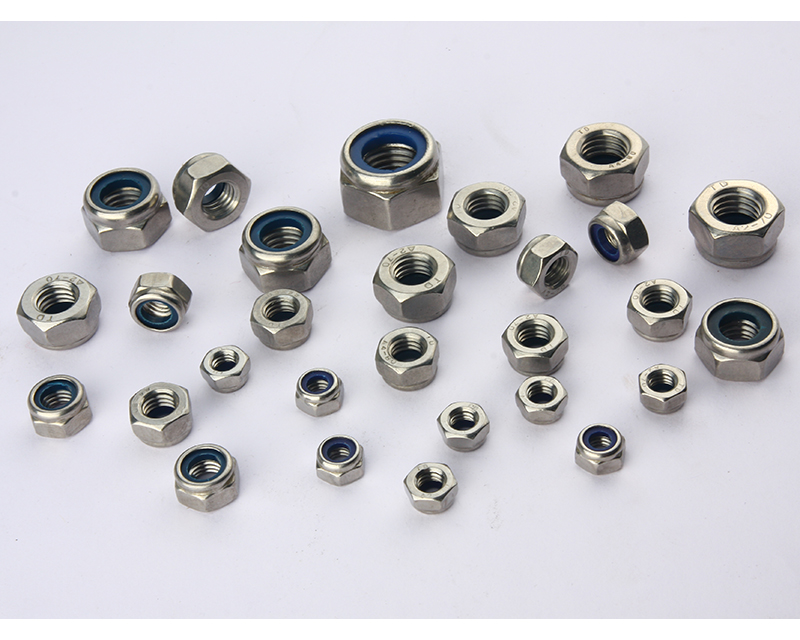

When it comes to securing metal structures, I always choose galvanized carriage bolts and nuts for their unmatched durability and corrosion resistance. These bolts are perfect for heavy-duty applications where strength and reliability matter most. Whether you're involved in construction, manufacturing, or any industrial project, you’ll find that these fasteners hold up exceptionally well under various conditions. I’ve noticed that buyers appreciate the ease of installation, as their design allows for a snug fit and enhanced load distribution. Plus, with a smooth surface, they reduce the chances of wear and tear on the connected materials. Select the right size and gauge to fit your needs, and you’ll see how galvanized carriage bolts and nuts can elevate the quality of your work. Don’t settle for less when it comes to fastening solutions; trust in galvanized options that deliver consistent performance over time.

Galvanized Carriage Bolt And Nut Guarantees Peak Performance Where Innovation Meets 2025

In the fast-evolving world of industrial hardware, finding components that ensure reliability and performance is crucial. Enter the galvanized carriage bolt and nut, designed to provide unparalleled strength and resilience for all your fastening needs. As we look toward 2025, these essential components are not only meeting industry standards but exceeding them through advanced manufacturing techniques and innovative design. The galvanized coating offers superior corrosion resistance, making them ideal for outdoor and high-humidity environments. This durability is vital for industries like construction, automotive, and manufacturing, where performance can make or break a project. Furthermore, as global procurement demands rise, so does the need for quality assurance and consistency. Innovative production processes ensure that each bolt and nut are produced with precision, allowing for seamless integration into any project. The ability to meet diverse applications—ranging from heavy-duty machinery to intricate assemblies—highlights the adaptability and reliability of these fasteners. When you choose galvanized carriage bolts and nuts, you are investing in a solution that not only enhances operational efficiency but also guarantees peak performance for years to come in an ever-competitive market. This commitment to quality and innovation prepares businesses for the challenges of the future.

Galvanized Carriage Bolt And Nut Guarantees Peak Performance Where Innovation Meets 2025

| Dimension (mm) | Material | Coating Type | Load Capacity (kg) | Applications |

|---|---|---|---|---|

| 10 x 50 | Steel | Galvanized | 200 | Construction |

| 12 x 75 | Stainless Steel | Zinc Plated | 300 | Heavy Machinery |

| 16 x 100 | Carbon Steel | Hot-Dip Galvanized | 500 | Bridge Construction |

| 20 x 120 | Alloy Steel | Powder Coated | 800 | Industrial Applications |

Related Products