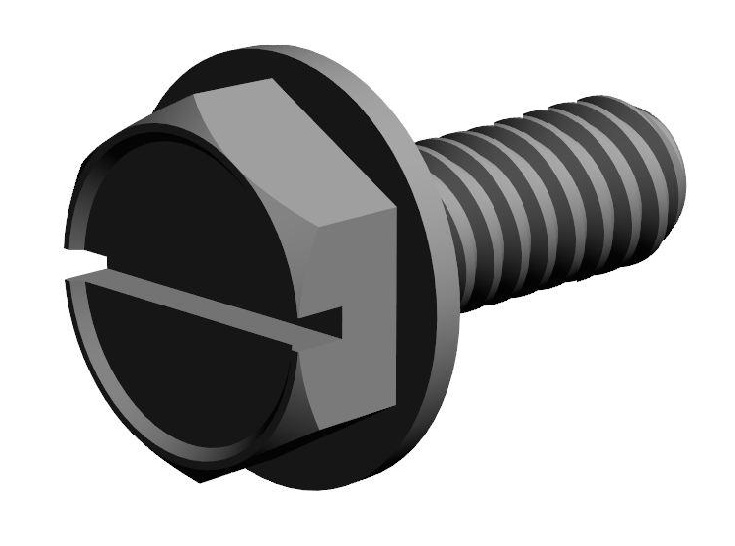

Custom Pan Head Screw for Efficient Assembly and Reliable Performance

When I think about securing projects, custom pan head screws come to mind as a go-to choice for reliability and strength. These screws are designed with a flat bearing surface, perfect for various materials. I often find that they provide excellent holding power and a sleek finish, ideal for applications in electronics, automotive, and furniture. If you’re searching for tailored solutions, you’ll appreciate how customizable these screws are, catering to specific thread sizes and materials. I’ve seen firsthand how our top-notch manufacturing processes ensure high precision and durability. Whether you need a small batch or bulk quantities, we’ve got you covered. Plus, with our competitive pricing and swift delivery, meeting your project deadlines becomes that much easier. Trust me, investing in quality custom pan head screws from a reliable supplier can make all the difference in your operations. Let’s get your project moving!

Custom Pan Head Screw Delivers Unmatched Quality Winning in 2025

In the competitive landscape of hardware manufacturing, the demand for high-quality components is at an all-time high. As we look towards 2025, one particular product stands out: the custom pan head screw. Designed for versatility and built to last, these screws meet the rigorous standards of various industries—from automotive to construction. Their unique pan head design provides a larger bearing surface, ensuring a secure fit and improved load distribution. This makes them not only reliable but also perfect for applications requiring deep seating and stability. The ability to customize these screws allows for tailored solutions that fit specific project requirements. Whether it's adjusting the material for corrosion resistance or modifying dimensions for unique applications, the custom pan head screw caters to diverse needs while maintaining high quality. Manufacturers can enhance their product offerings by integrating these superior screws into their assemblies, driving both efficiency and effectiveness. Moreover, robust quality control measures ensure that each screw meets international standards, giving buyers the confidence they need in their procurement processes. Investing in custom pan head screws can significantly impact overall project success and operational efficiency. As global markets continue to evolve, sourcing high-quality components remains a top priority for procurement professionals. The custom pan head screw not only provides unmatched quality but also represents a strategic advantage for businesses aiming to thrive in 2025 and beyond. By prioritizing premium materials and innovative designs, companies can position themselves for growth, ensuring they remain competitive in the dynamic world of hardware manufacturing.

Custom Pan Head Screw Delivers Unmatched Quality Winning in 2025

| Specification | Material | Coating Type | Size (mm) | Tensile Strength (MPa) | Production Lead Time (Days) |

|---|---|---|---|---|---|

| M3 Pan Head | Stainless Steel | Zinc Plated | 3.0 | 600 | 15 |

| M4 Pan Head | Carbon Steel | Black Oxide | 4.0 | 500 | 10 |

| M5 Pan Head | Aluminum | Anodized | 5.0 | 400 | 20 |

| M6 Pan Head | Brass | Nickel Plated | 6.0 | 300 | 25 |

Related Products