Custom Bushing Solutions for Precision Engineering & Optimal Performance

When I needed a reliable solution for our machinery alignments, I turned to custom bushings. These versatile components fit perfectly in various applications, drastically reducing wear and increasing efficiency. I found precisely what we were looking for in terms of quality and customization. With options tailored to our specifications, we managed to enhance our operations significantly. What struck me the most was the ease of ordering. The ability to customize dimensions and materials allowed us to tackle specific challenges we faced. Plus, the turnaround time was impressive, ensuring we keep projects on schedule. If you've been considering making an upgrade, custom bushings are a game changer for any manufacturer. They not only improve performance but also extend the lifespan of your equipment. Let's connect and discuss how we can elevate your production line with high-quality custom bushings tailored just for your needs.

Custom Bushing Is The Best Delivers Unmatched Quality

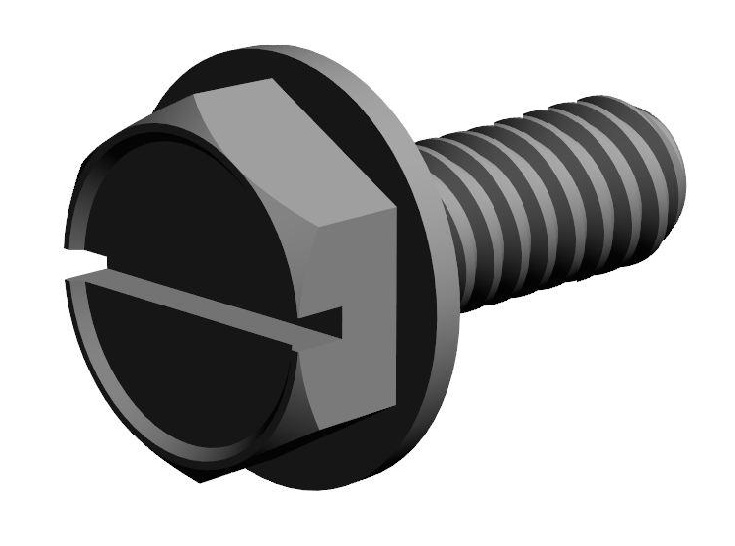

In the world of industrial hardware, the demand for custom solutions has never been higher. A unique aspect of this is the custom bushing, which offers unparalleled quality and versatility for various applications. Designed to fit specific requirements, custom bushings not only enhance performance but also reduce the likelihood of equipment failure. By tailoring components to meet precise specifications, manufacturers can improve efficiency and effectiveness across various industries, from automotive to machinery. The manufacturing process of these custom bushings involves advanced techniques and rigorous quality control measures, ensuring that each product exceeds international standards. Utilizing high-grade materials and innovative production methods allows businesses to achieve optimal durability and functionality. For procurement professionals seeking reliable components, investing in custom bushings can lead to significant cost savings and operational advantages. In conclusion, the choice of custom bushings stands out as an intelligent investment for companies looking to optimize their supply chain and improve product performance. With unmatched quality and a commitment to excellence, sourcing these tailored components meets the complex demands of the modern market. Embracing custom solutions paves the way for enhanced productivity, ultimately driving business success.

Custom Bushing Is The Best Delivers Unmatched Quality

| Material Type | Diameter (mm) | Length (mm) | Tolerance (mm) | Application |

|---|---|---|---|---|

| Nylon | 25 | 50 | ±0.05 | Automotive |

| Bronze | 30 | 60 | ±0.02 | Heavy Machinery |

| Aluminum | 20 | 40 | ±0.03 | Aerospace |

| PTFE | 15 | 35 | ±0.01 | Chemical Processing |

Related Products