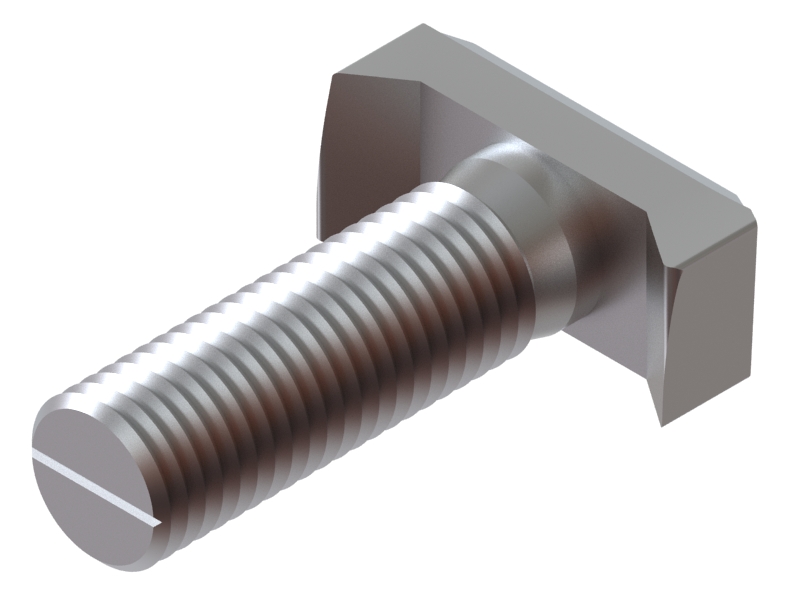

High-Quality Chrome Plated Bolt for Durability and Performance Needs

When I needed a reliable and high-quality fastening solution, I turned to chrome plated bolts. These bolts not only provide exceptional strength but also offer corrosion resistance, making them ideal for a wide range of applications. The polished finish gives them a sleek look, perfect for those projects where appearance matters. If you're in a situation where you need durability and style, investing in chrome plated bolts is the way to go. They have a lot of benefits—easy to install, resistant to rust, and they hold up under pressure. I guarantee you won’t regret choosing these for your next project. Let me tell you, customers like you are always impressed with their performance! Whether you’re working in automotive, construction, or manufacturing, these bolts will meet your needs. Don't miss out on strengthening your inventory with the best fastening solutions out there!

Chrome Plated Bolt Manufacturer in 2025

In 2025, the demand for high-quality chrome plated bolts is expected to surge, driven by various industries seeking durability and aesthetic appeal. As global procurement specialists turn their attention to reliable suppliers, chrome plating has emerged as a preferred option for enhancing the lifespan and corrosion resistance of fasteners. These bolts not only provide robust performance in harsh environments but also contribute to the overall aesthetics of finished products, making them an essential component in industries like automotive, construction, and manufacturing. Choosing the right manufacturer can be pivotal for businesses aiming to secure quality products that adhere to international standards. The ideal supplier should offer a comprehensive range of chrome plated bolts tailored to diverse applications, ensuring that procurement managers can find the right specifications for their projects. Moreover, advanced manufacturing techniques and rigorous quality control processes are crucial attributes that distinguish leading manufacturers in the competitive global market. As we approach 2025, it's vital for procurement teams to stay informed about trends in chrome plated bolt production, including innovations in materials and coatings that enhance performance. Collaborating with a reputable supplier not only ensures the availability of high-quality products but also opens the door to customized solutions that meet specific needs. By understanding the importance of selecting the right partner, businesses can achieve greater efficiency and reliability in their operations, paving the way for success in an ever-evolving marketplace.

Chrome Plated Bolt Manufacturer in 2025

| Dimension | Material | Plating Type | Load Capacity (lbs) | Corrosion Resistance | Certification |

|---|---|---|---|---|---|

| 1/4" x 2" | Carbon Steel | Chrome | 1000 | High | ISO 9001 |

| 3/8" x 3" | Stainless Steel | Nickel-Chrome | 1500 | Excellent | ASTM A193 |

| 1/2" x 1" | Alloy Steel | Chrome | 2000 | Moderate | DIN 931 |

| 5/16" x 2.5" | Carbon Steel | Zinc-Chrome | 1200 | Good | CE Marked |

| 7/16" x 4" | Stainless Steel | Trivalent Chrome | 1800 | Very High | RoHS Compliant |

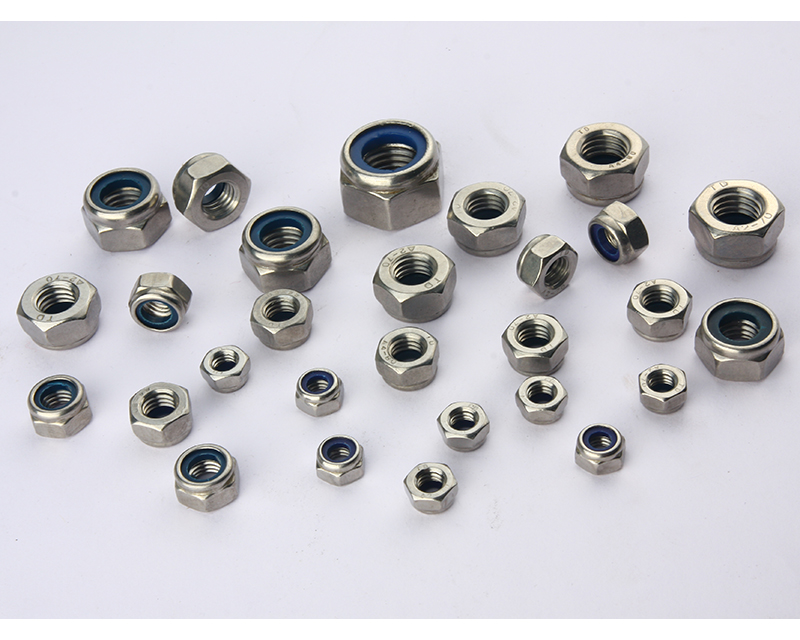

Related Products