China Metal Fabrication: Quality Solutions for Your Manufacturing Needs

When it comes to precision and reliability in China Metal Fabrication, we've got you covered. I understand the challenges that come with sourcing quality metal components for your projects. That’s why I’m proud to say our fabrication services consistently meet the high standards and customization needs of businesses like yours. Whether you’re needing prototyping or large-scale production runs, our team works closely with you to deliver tailored solutions that fit your specific requirements. We’re not just about meeting deadlines; we focus on building lasting partnerships with our clients. Our state-of-the-art technology and skilled workforce ensure every piece is crafted with attention to detail. Plus, our commitment to sustainable practices means you can feel good about the impact of your sourcing choices. Ready to elevate your production capabilities? Let’s discuss how our China Metal Fabrication services can enhance your supply chain and drive your business success!

China Metal Fabrication Where Innovation Meets 2025 Supplies the World\u2019s Top Brands

In the rapidly evolving landscape of metal fabrication, innovation has become a crucial factor in meeting the demands of global brands. As we approach 2025, manufacturers are expected to not only meet but exceed the expectations of quality, efficiency, and sustainability. Companies around the world are searching for reliable partners that can deliver precision-engineered products while adapting to the latest technological advancements. With advanced machinery and a skilled workforce, the metal fabrication sector is primed to support diverse industries, ensuring that top brands receive top-tier components. The integration of smart technologies such as automation, IoT, and AI into the manufacturing process is revolutionizing the way metal fabrication operates. This shift not only enhances productivity but also improves accuracy, allowing for the creation of increasingly complex designs. Sustainability is also at the forefront, with manufacturers making significant investments in eco-friendly materials and processes. By prioritizing sustainability, these manufacturers are setting a new standard, appealing to brands that recognize the importance of responsible sourcing in today’s market. Engaging with a responsive and innovative partner in metal fabrication can open up new avenues for procurement strategies. Whether it’s automotive, aerospace, or consumer goods, having access to cutting-edge capabilities and a commitment to excellence is essential for businesses looking to enhance their supply chains. As the fabricator landscape evolves, forward-thinking companies will be positioned to not only fulfill current demands but also drive the future of manufacturing on a global scale.

China Metal Fabrication: Where Innovation Meets 2025 Supplies the World's Top Brands

| Category | Material Type | Application | Production Capacity (Units/Month) | Certifications |

|---|---|---|---|---|

| Metal Stamping | Steel | Automotive Components | 50,000 | ISO 9001, TS 16949 |

| CNC Machining | Aluminum | Electronics Enclosures | 30,000 | ISO 9001 |

| Metal Fabrication | Stainless Steel | Kitchen Appliances | 20,000 | CE, RoHS |

| Laser Cutting | Carbon Steel | Structural Components | 15,000 | ISO 9001 |

| Metal Welding | Titanium | Aerospace Parts | 10,000 | AS9100 |

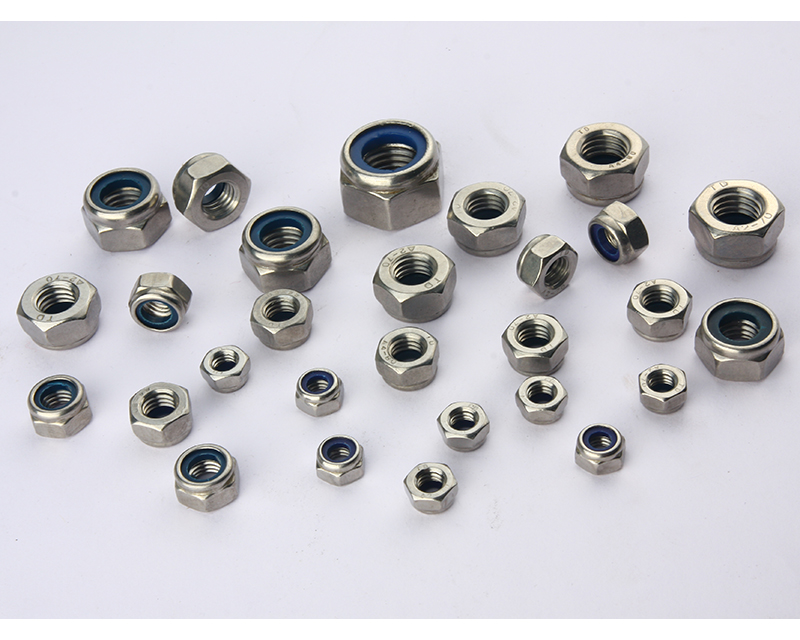

Related Products