Top Carriage Bolts and Nuts Factories for Quality Manufacturing

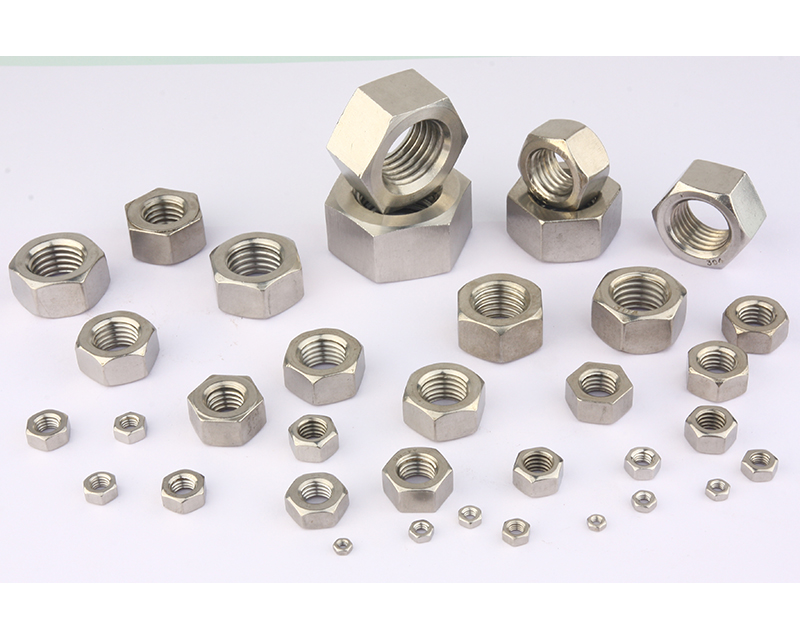

When I needed reliable fasteners, I turned to Carriage Bolts and Nuts Factories for the right solution. These high-strength bolts and nuts are specially designed for structural applications, ensuring your projects maintain integrity and durability. Working with manufacturers who prioritize quality and precision, I found that their consistent production processes cater to diverse industrial needs, making them perfect for my construction and woodworking projects. I was particularly impressed by the various sizes and finishes available, allowing for easy customization based on project requirements. The quick turnaround time really caught my attention too, ensuring I get my supplies without unnecessary delays. Whether you're a contractor, furniture maker, or engaged in another trade, sourcing from Carriage Bolts and Nuts Factories will give you peace of mind knowing every fastener meets stringent quality standards. Let's simplify your procurement process and ensure your projects are built to last!

Carriage Bolts And Nuts Factories Service Factory-Direct Excellence

When sourcing high-quality carriage bolts and nuts, buyers often seek manufacturers that prioritize excellence and direct service. Carriage bolts are essential components in various applications due to their unique design that allows for secure fastening, preventing the bolt from turning when a nut is tightened. Direct access to manufacturers like those in specialized hardware factories ensures that buyers receive not only premium products but also valuable insights into customization options based on specific project needs. These factories typically offer a range of sizes and materials for carriage bolts and nuts, catering to diverse industrial requirements. By collaborating closely with manufacturers, global buyers can benefit from streamlined communication and quicker response times, leading to efficient procurement processes. Additionally, factory-direct services often mean lower costs without compromising quality, making it an attractive option for those looking to maintain budgetary efficiency while ensuring product reliability. Investing in a partnership with a reputable factory also emphasizes commitment to quality control. Many factories implement rigorous testing procedures to ensure that each batch of carriage bolts and nuts meets international standards. This not only enhances the end product’s performance but also builds trust between the manufacturer and the buyer, fostering long-term business relationships that thrive on quality and reliability. As global industries continue to evolve, aligning with top-notch hardware factories becomes a strategic advantage in maintaining competitive edge.

Carriage Bolts And Nuts Factories Service Factory-Direct Excellence

| Factory Location | Production Capacity (units/day) | Material Types | Quality Certifications | Sustainability Initiatives |

|---|---|---|---|---|

| Shanghai, China | 5000 | Steel, Stainless Steel | ISO 9001, ISO 14001 | Recycling Program, Energy Efficiency |

| Bangalore, India | 3000 | Mild Steel, Aluminum | ISO 9001 | Water Conservation, Waste Reduction |

| Berlin, Germany | 4000 | High-Strength Steel | DIN, ISO 9001 | Sustainable Sourcing, Emissions Reduction |

| Los Angeles, USA | 2500 | Brass, Stainless Steel | ANSI, ISO 9001 | Carbon Footprint Reduction, Renewable Energy Usage |

Related Products